Hi people, I want to open a discussion about thick plates. What are your thoughts or experiences with thick plates?

I will be glad if you can join this discussion and share your thoughts.

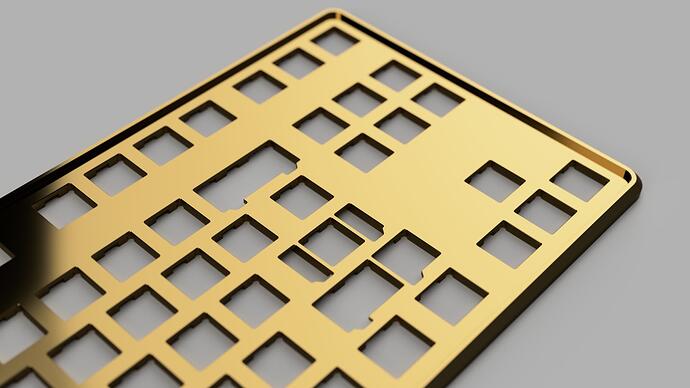

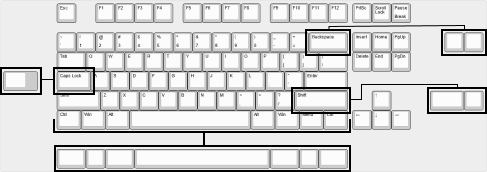

So, I have a serious vision, shared with some other enthusiasts, about an aluminium keyboard housing with thick plate. Currently, we want to experiment with brass (copper-zinc alloy) as the material and are trying to use a thickness of 3.5 mm. The housing’s design is in progress (still making sure the dimensioning & tolerance and discussing manufacturing constraints) and we will have a discussion about it very soon here.

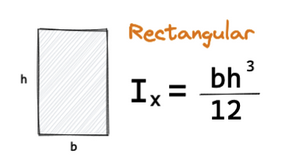

The reason behind this attempt came from tons of discussions about plate material. According to many enthusiasts, brass is the “thockiest” material. By experimenting with denser materials to achieve better sound and stability, a question emerged: What if we added even more mass to the plate? Adding thickness increases the mass and inertia. Polymer plates are too bendy, more prone to chipping, and has static issue. Composite plates (mostly and specifically carbon fiber) are too loud (high stiffness-to-weight ratio). Last, tray mounts or integrated plates are too rigid, transmitting too much vibration to the housing and eventually to the table. After few years in the hobby now I’m ready for this expensive experiment.

A solid brass slab is expected to be machined for about 28 hours said the CAM engineer. This plate design is about 900 grams when finished.

Well, that number scares me hahaa imagine if we go all-brass. That would be very heavy and too expensive… This https://youtu.be/iq653ZKbLbA?t=263 but TKL…

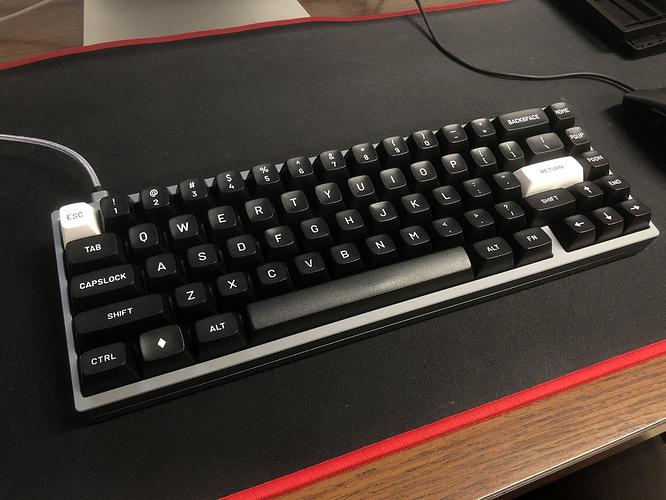

The plate’s bezel, as seen in the pictures, helps to center the plate. Inside the housing, cushions will keep the plate centered, prevent contact with the housing wall, and help keep dust on top for easier cleaning.