Yea, my ridiculously slow brain thought “programming” means all CAM job, making G code things blabla. It includes the setup time, you’re right.

Personally, that’s not a wild guess ![]() . The natural freq. of softer material is always lower than the higher one. So the possibility of resonance occurring will be higher in polymers. It makes the outcome louder (amplitude spikes) but in a warmer tone (thocky). It is hard to make a concise explanation but bear with me. POM is a harder polymer than PC but denser (heavier), and most people love the sound outcome. How about brass vs other popular metals like AA-6061? Brass is heavier and stiffer than AA-6061. So I expect a warmer clack or the thockiest clack possible for my design. LOL can’t believe I say this.

. The natural freq. of softer material is always lower than the higher one. So the possibility of resonance occurring will be higher in polymers. It makes the outcome louder (amplitude spikes) but in a warmer tone (thocky). It is hard to make a concise explanation but bear with me. POM is a harder polymer than PC but denser (heavier), and most people love the sound outcome. How about brass vs other popular metals like AA-6061? Brass is heavier and stiffer than AA-6061. So I expect a warmer clack or the thockiest clack possible for my design. LOL can’t believe I say this.

I’m just avoiding polymers because of how bendy, easy to scratch (e.g. by switch puller ![]() ), and prone to static build-up they are. AA-6061 plates are pretty tricky. We all agree that many great-sounding keyboards use 6061 plates, but there are also many poor-sounding keyboards with similar specs aluminum plates that still struggle even after numerous modifications.

), and prone to static build-up they are. AA-6061 plates are pretty tricky. We all agree that many great-sounding keyboards use 6061 plates, but there are also many poor-sounding keyboards with similar specs aluminum plates that still struggle even after numerous modifications.

You said about space underneath the switches. It reminds me of that video about vintage keyboards by Youtuber chyrosran22. He stated how plasticky and roomy the vintage models are, which helps to emphasize the switches’ characteristics. I need to save your review because it also support Chyrosran22’s opinion. I’m also not very into the idea of deadening everything and making it SUPER mute. Strangely enough, some of them have plastic housings with steel plates that weigh more than a kilogram, making them even heavier and stiffer than my brass plate design.

We will see the result and evaluate it together. If necessary, we can rework the housing later.

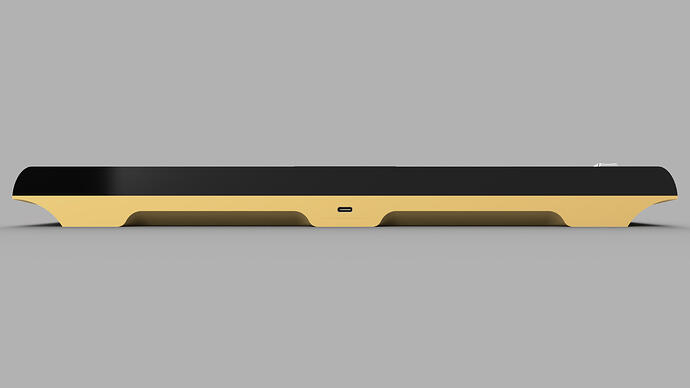

Wow, those are nice examples. The contouring design of my housing is not as complex as theirs because we can start with the least effort to produce a non-flat internal surface. If this doesn’t perform enough, we can try to add a more complex design. For now, I will keep it that way but give extra clearance beneath the switches (more roomy especially to X-Y axis directions) due to your opinion. Thanks for these! ![]()

Afraid that there is a possibility that it keeps happening, although we are unaware… perhaps not strong enough to ruin your MCU.

And the good thing about your thrice-zapped experience is the static chose to zap you instead of the electronics. It means you are less resistant than your office grounding system, assuming they really do the grounding job ![]()

Please make sure that the housing connects to the PCB or DB too!

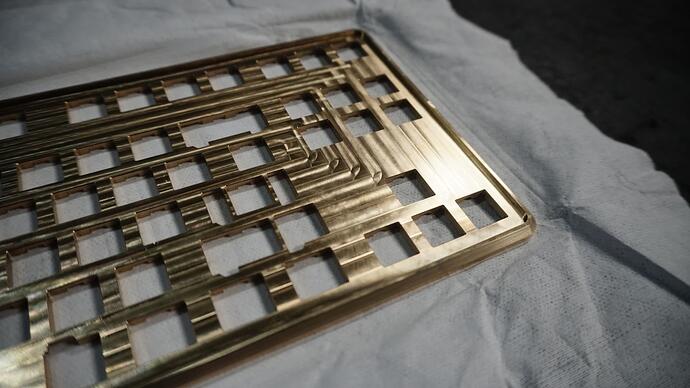

Came out pretty clean!

Looks fantastic!

I don’t know why as I’m not even hungry but I have the urge to see someone CNC a burger with this brass plate as the patty.

![]() umm maybe with some CNC coolant slurry sauce for an extra kick??

umm maybe with some CNC coolant slurry sauce for an extra kick??

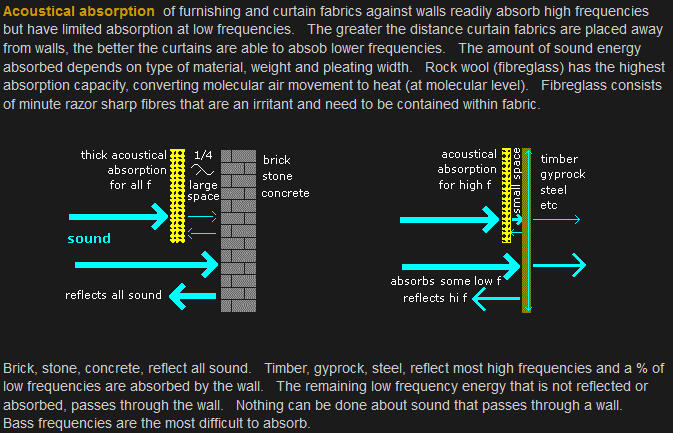

Guys, so i found this from Acoustics: Sound Absorption

These are two diagrams of the cross-section of the opera house wall design. I start to understand why @donpark in this post: Case material? What's the differences? - #2 by donpark said that aluminum (metal in general) is not inherently high-pitched material for keyboard housing and I think we will continue to use it as the housing material for years to come.

The weight-to-stiffness ratio of the metal is larger than the concrete’s. For concrete vs polycarbonate, the concrete has a smaller weight-to-stiffness ratio. So, you need to use denser material but keep the stiffness as low as possible.

![]()

You can imagine this part as the PCB (polymer material), which can eventually absorb most of the noise that bounces around in the area between the PCB and the internal surface of the bottom part. The aluminum housing will absorb some of the noise and pass some of the low-frequency sounds to the surroundings or the ‘thocky’ sound as the leftover, I suppose. I think tape mod also adds more power here but inserting a silicone damper or too much foam will make it too muted and deaden your beautiful premium switch character.

Did I miss something?

Nope, that all makes perfect sense to me & aligns with my experiences with custom KBs.

Yk what the plate is finished and it won’t work unless we have a housing. This effort is meaningless if we stop here. So, the design is meant to be an isolated bottom-mounting plate. It will sit on a few soft rubber cushions around shore 30A stiffness. Eventually, after digesting much input from our community and making some adjustments to the design, it’s time to share more of my work.

In this work, I am not making any new things here. Just try to refine everything good this community has had from its early days until now. I just want to replace my aluminium tray mount keyboard that has already reached its plateau of modification. The conclusion is that it’s too rigid, and the ping still remains. Adding more foam or any polymer filling doesn’t help much. The pingy noise just turns into a pongy noise but decays rather quickly, not really a hollowness tone. Can’t believe I’m saying this. Well, I just have a 0.7 USD made-in-china microphone that came without a box. Can’t precisely record the noise. LOL but have enough money to go to a machining shop SMH. Anyway, that tray mount keyboard is still a hero for me since it’s the one who cut the frustration made by my already-dead membrane keyboard many years ago.

As you can see, this plate does not fit in any housing design in the wild. I design specifically a SUPER thick aluminium alloy housing for it. Again, I avoid polymer material due to some reasons.

It’s pretty irritating since I might not be able to produce the vintage-like sound that comes from many vintage keyboards with spacious injection-molded plastic housings with super thick walls and ribs. I still managed to make this design a moderately spacious clearance underneath its PCB to mimic those vintages.

Plastic hardware in fact most of the time can effortlessly eliminate high-frequency noise. But They can unintentionally vibrate and blend into the keypress symphony. They are too lightweight. Let’s make it hefty (inertia increased) resulting in its capability to not easily vibrate. Maybe that is the reason why some vintage keyboards have a steel plate near the bottom part. Sure, this hefty and stiffer aluminium housing can resonate if you can type hundreds of thousands of words per minute, which is unnatural.

You might want to check my previous post: Thick brass plate in TKL layout (Done machining update) - #28 by Dominus

Ummm… Does anyone have a vision for a clean, screwless-look housing design but does not want to use a magnetic cover gimmick for some reason? If so, I designed a cover plate to cover the bolts that mimics the hotshoe cover on a camera but uses a metal ball plunger as its locking mechanism. You will find no bolt joint holes on its entire surface.

What do you think?

This is a clean monolithic design that weighs around 4 kg/8.8 lbs for brass plate assembly and around 3.4 kg/7.5 lbs for full-aluminium assembly. I will make the prototype very soon. After the prototype is done, let’s review it together. If it turns out to be good and truly meets our community standards, I want to elevate this into a much more professional project.