Time to give some details on the case itself !

You’ll see that the design is very classic and simple and a completely different vibe than the Winghead and Manta75.

Reason of the simplicity is that I am not a professional designer and don’t want to risk overdoing things and obtain something ugly to look at; I am just a NERD that like to hack and make things when at home.

Another benefit of selecting a simple design is that all shapes and dimentions are all well defined (it is difficult to specify organic curves in a technical drawing) and this reduces misunterstanding issues with the CNC provider.

And of course I took a lot of inspications of existing keyboards.

To summarize the inspiration and the general look, the Aquanaut is a mix of a Geon’s F1-8X 722 and a Smith & Rune Iron 165 with a tad of OTD Koala vibes

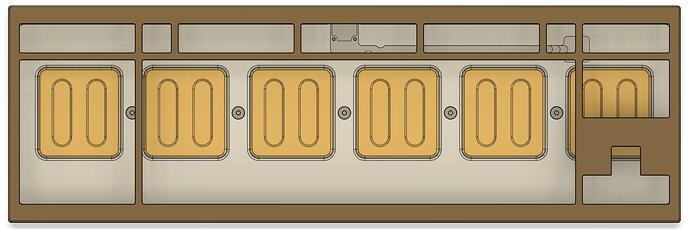

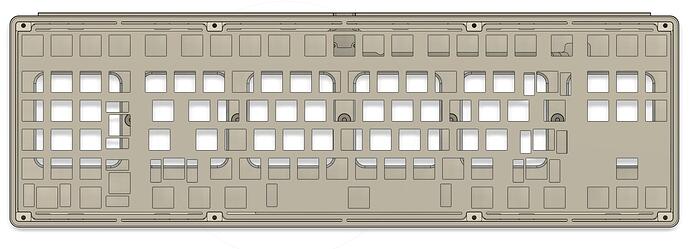

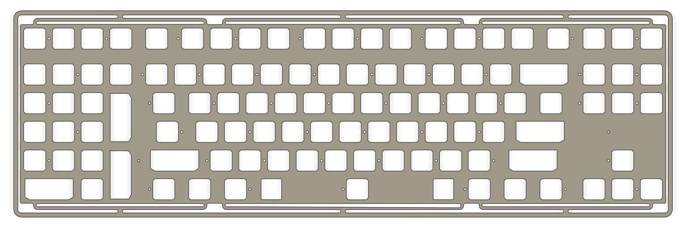

Here it is from the top:

This is a very boxy look with corner radiuses of only 2mm and top fillet of 1mm, just what is needed to still have something comfy to the touch but not more.

As for the top and side bezels, those are bigger than usually found in Korean standards (that are 0.5u top/botton and 0.25 on the sides) but are kept to a minimum size given the mounting system used.

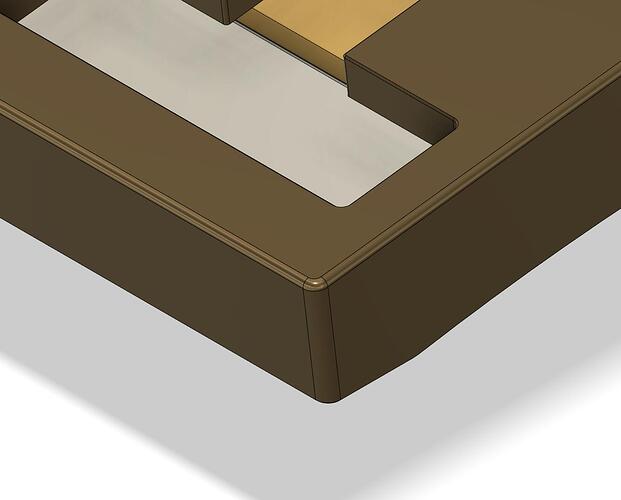

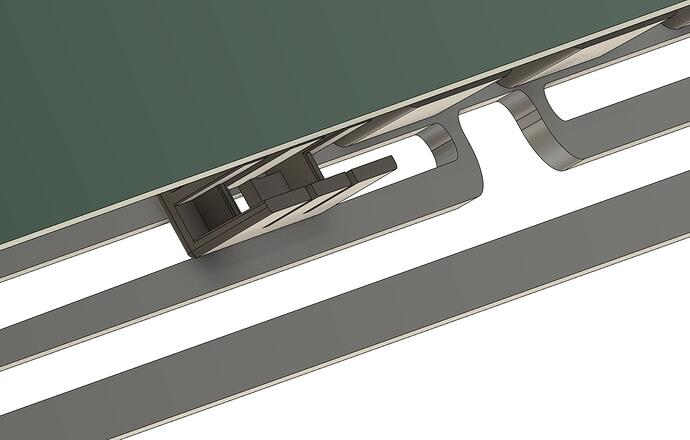

Here is a closeup for better view of corner radius and fillet:

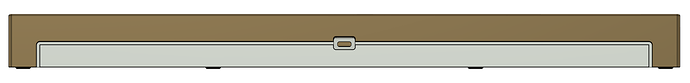

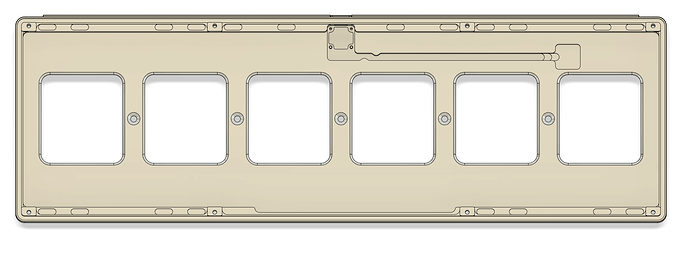

As for the back:

This is where you can see the most Iron 165(and 180) inspirations. I always loved the back of those old Smith & Rune keyboards and their boxy look.

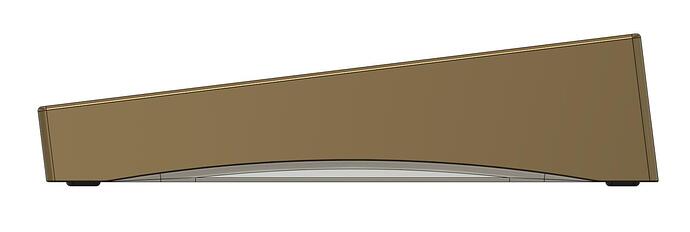

And now the side:

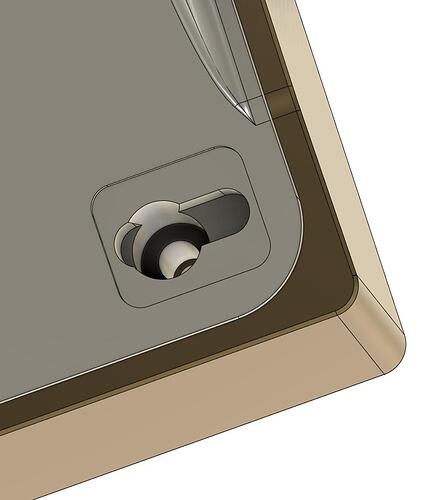

A small OTD Koala curve (it is an arc circle with a well defined radius) of 5mm tall and 5 mm deep, just what is needed to be able to grab the board easily.

You can see here that the Koala feature is done very closely to what was done on the old OTD board, just adding a bit of curves on it to not cut my fingers when grabbing the board. It is also less deep than in original Koala design (at around 2cm) to take into account the bottom internals.

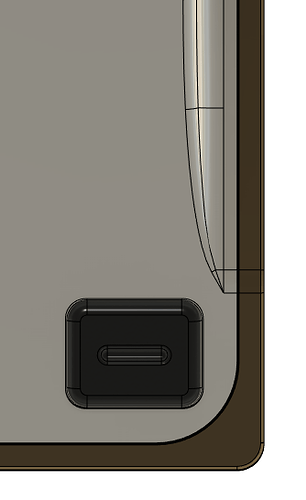

And you also have a closeup of one of the 8 feets, those are original Geon F1-8X feets to have a ‘screwless’ design.

They nicely hide the 8 screws used for assembly.

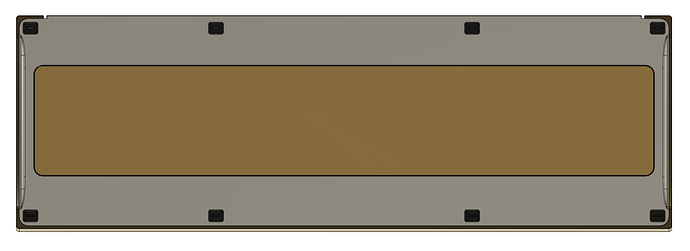

As for the bottom:

You can see the 8 feets, the big brass (or maybe copper ?) weight and the small Koala features.

The weight traverses the whole bottom part like seen in the previous pictures. I once considered to make the whole bottom piece full brass but the board would have weighted more than 6KG ! Totally absurd, so no

Here is a better view of the bottom and weight assembly:

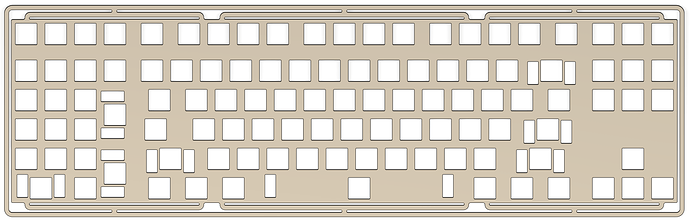

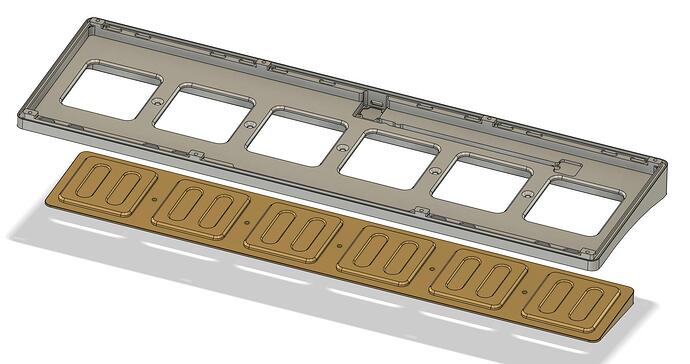

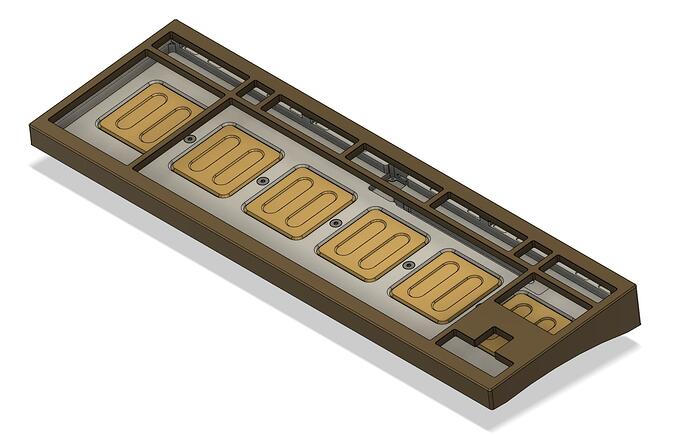

The plate and bottom assembly is like this:

This may explain a bit more why the shape of the plate.

And without the plate:

And a perspective closeup:

You can better see where the 3mm Oring will fit all around the bottom and after the screw poles(the same feature is present on the top part). Just like the F1-8X Viton Orings will be used.

There are 4 small rounded rectangle shaped cutouts for each leaf spring to optionnally put 3mm gaskets in them, this to tune the bounce depending on taste and plate material. There are none under the spacebar as there are no space for them to accomodate Topre spacebar stabilizer parts and to have a tad more bounce in this area.

And a few perspective views to finish:

Some numbers:

The estimated weight for top + bottom + weight is around 3.8KB, it is a heavy boi but not absurdly heavy considering the size.

The lip front height is around 17.8 mm and the adjusted front height is 19mm. The feets adds 1mm. The typing angle is 7 degree. Those combined should make a comfortable typing experience.

Work to be done:

I still need to double/triple check that dimensions are correct and that no features are missing.

Also have to decide the CNC manufacturer and the finishes I’ll want.

This will take me quite some time …

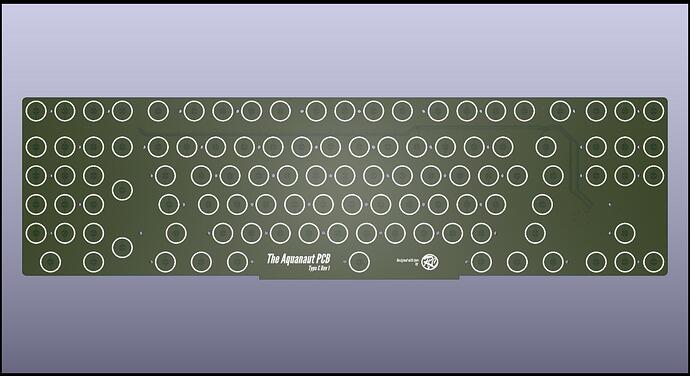

![]()

![]()