Seriously awesome dude. You’re as deep in this hobby as it gets.

I think I’m just coming to it from the other end. I’m already familiar with electronics and programming, but I know very little about switches, springs, caps, plates, cases, gaskets, acoustics, etc.

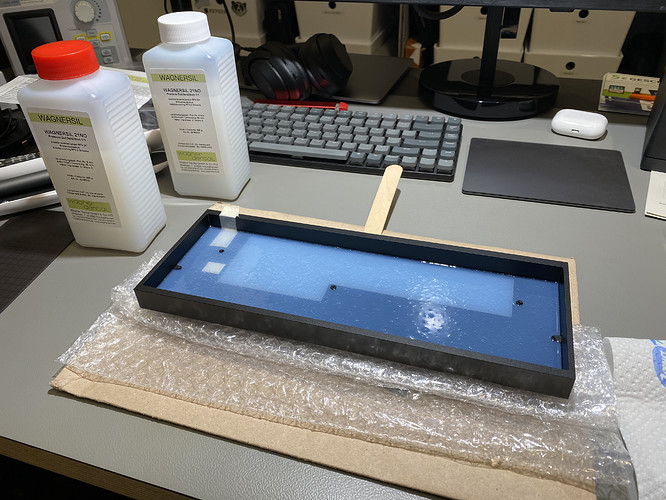

I haven’t seen anyone use dental silicon before. At least you know it’s food safe.

I can lick it any time I want!

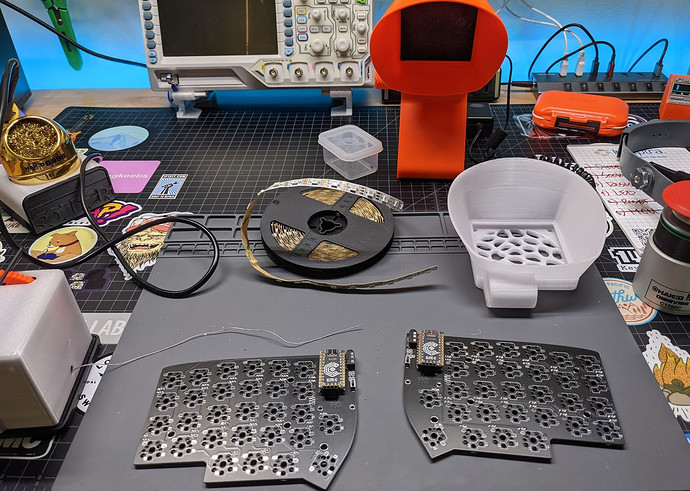

Working on the board podcast switch break in machine. It needs a little more TLC and some sacrificial DSA keycaps. Wired a switch up to the keyboard to see keep track of actuations.

I wanted to try this when I saw the board podcast video, but I don’t really know anything about 3d printing. I may have to hit up a friend.

I’ve assembled a quick one - YMDK Melody96 with Infinikey 808-Boom keycaps and Gateron blacks as a present for a friend who is a musician.

That little motor is not up to the task. It’s loud AF and if it isn’t perfectly balanced with the wheels it gets stuck. I ran it for about 15 min, not continuous, yesterday and 3 min today it’s just off. I think it ended up being about 5000 actuations.

It looks like me keebs used a 3d printer machine rod to control his. But that would mean I need to remodel the parts. Alternatively I need to find a bigger motor but still compatible with an m4 shaft or some kind of coupler.

@fatalruin this was my first 3d printed anything. I used the existing model and TreatStock. It came out ok. I had to drill it out for the motor to fix which was more difficult then I expected because parts of it were hollow and the PLA plastic kind of doesn’t like to be messed with by power tools.

Motor upgrade!

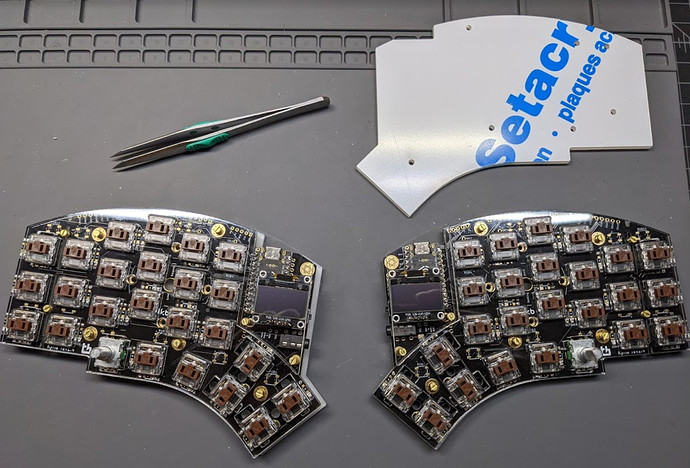

And the finished keyboard (Chocolad, by @jmnw). I had to bodge the TRRS cable on one side to connect it to TX instead of RX, and I put all the diodes the wrong way, and had to fix it in software, but otherwise it works great with CircuitPython.

Getting closer, last steps are to design up a high profile, 3D printed case, and apply the keycaps.

Then I need to get working on the Jabberwocky next.

This is bonkers and I love it

WORD. You’re a wicked genius bud. Glad you’re on our team.

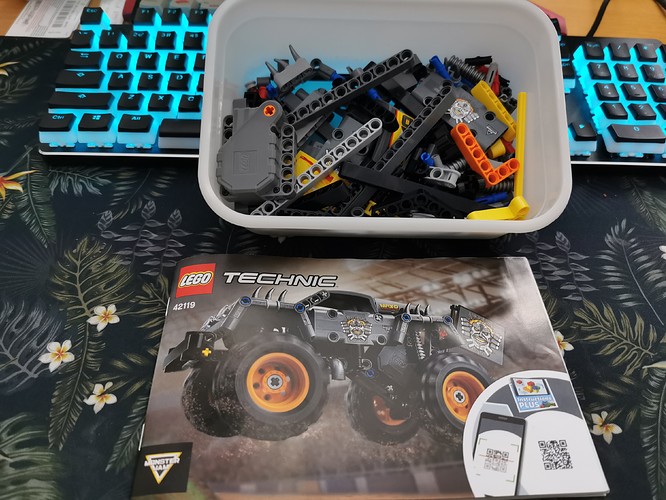

Drilling holes into a plate for my first keyboard build. It was super tiring and the holes ended up being too small lmao.

Get yourself a high speed steel drill bit for making holes in metal plates. They are made specifically for drilling into metal, also they cut it much cleaner & faster than regular carbide bits. I also recommend using a center punch to get a good starting point & to keep the drill bit from “walking” away from where you want the hole centered. Drilling metal is much, much easier with those bits & punch mark to start IME.

Edit: Oh yeah almost forgot, since you already have holes drilled in that plate but they are too small you’ll want to use a high speed steel stepped drill bit to enlarge them. That’ll make widening them much easier than trying to use just a bigger straight shank drill bit. Even if it’s a high speed steel one.

Never heard of these before. I’ll definitely be investing in one of these for future projects. Thanks!

Was working on fixing up a Realforce that came in yesterday with some help from Lady Gaga… there was one key that had a weird resistance to it, and very pronounced spring crunch. Strange.

Imagine my surprise when this was the problem…

The key had two springs underneath it, combined into a strange frankenspring (pictured, the freed spring)!!! This is straight from Topre since the warranty sticker was still intact when I received the keyboard… What a bizarre conclusion to my Sunday sleuthing!

Or am I just being daft and forgetting some keys really do have two capacitive springs underneath?!

A Lily58Pro in progress having to re-solder the pins on the Elite-C’s since I can never get the orientation on these correct. Going to add some excessive RGB under-lighting too, because why not?

Also printed a new clear hood for the soldering fan (adding some “lightness”).