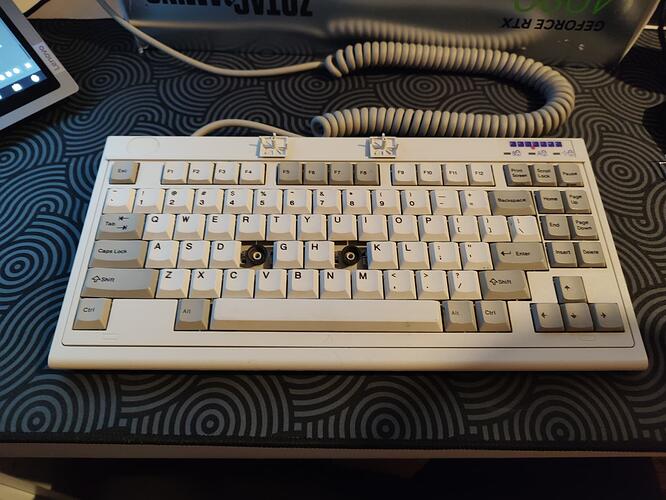

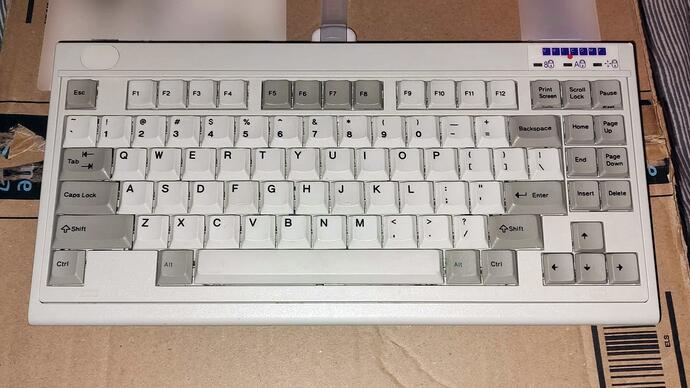

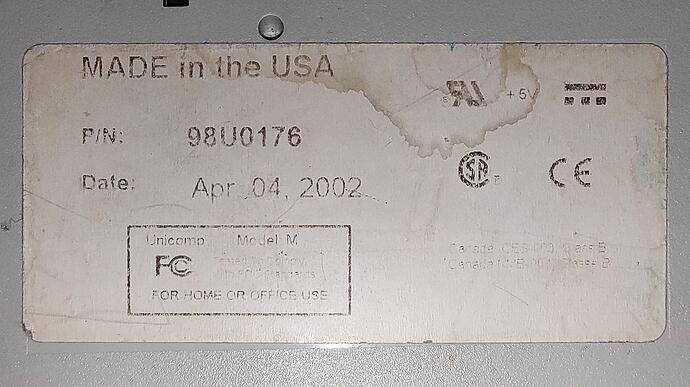

As I posted the other day in What did you get in the mail today? (Part 2) - #599 by SharktasticA, I recently received a 2002 Unicomp-branded Model M4 (P/N 98U0176) along with some other keyboards that require restoration. For those who are unaware of them, Models M4 and M4-1 were slim and small form-factor Model M variants that used IBM buckling sleeve tactile keyswitches that also powered many early IBM ThinkPad laptop keyboards (Models M6 and M6-1). M4 had no pointing stick, and M4-1 had a TrackPoint II stick and two mouse buttons.

Both keyboards are derived from the Model M3 family (IBM PS/2 L40SX laptop keyboard and numpad) and have detachable numpads available for them. Buckling sleeves are an interesting keyswitch used by many members of the Model M family that don’t use buckling springs. They’re partially rubber based but they’re not shaped or used the same way as rubber domes. Overall, they’re snappy and very tactile. Thinking they are like buckling springs will leave you disappointed, but thinking they are like your average rubber dome may leave you pleasantly suprised. I view them as “IBM’s last stand” before even their keyboards became generic/ODM/OEM rubber dome designs. You can read more about M4/M4-1 on my website and Type Retro has a nice typing demo of an M4-1.

On the surface, it looked like this keyboard was just very dirty but there are some issues inside. I’ve taken this opportunity to take some photos for my wiki and to show you what’s inside and what I’ve done so far.

Keyboard frame

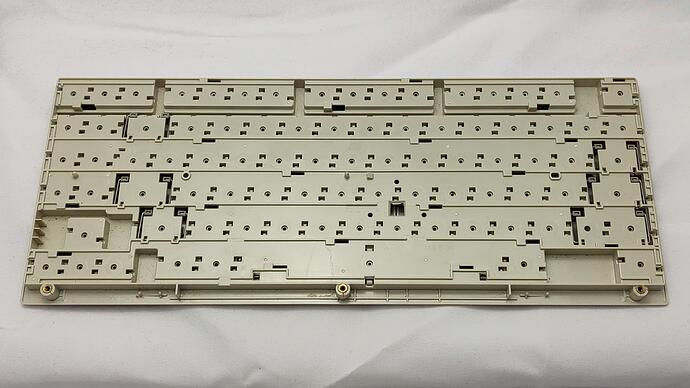

Like most Model Ms, M4/M4-1 has a keyboard frame (aka, a “barrel plate”) used for guiding keyswitch components to their needed positions. In this case, keycaps and sleeves above their correct position above the membrane assembly’s contact points. The sleeves are only used for tactility generation and as a return force, the keycap itself actually pushes on the membrane. All those circles you see are the keycap plungers at rest. You can also see the opening for a would-be TrackPoint stick. M4/M4-1 frames are made of PC+ABS.

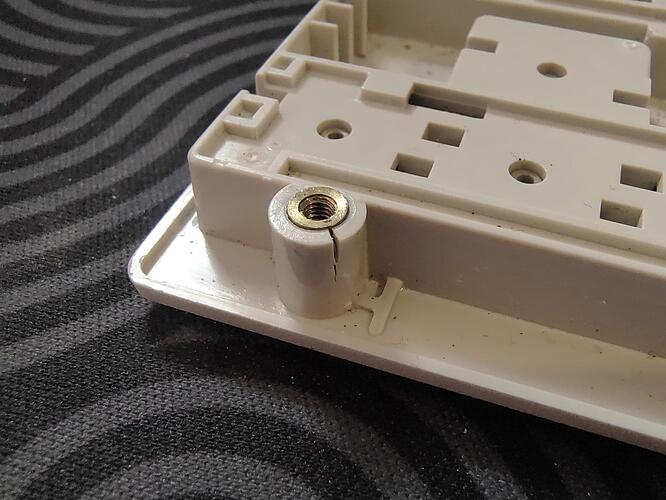

The frame is screwed into its cover set via three screws towards the bottom. The plastic around them is known to weaken with age and may crack. Usually, glue is a simple fix. However, for this keyboard, it appears a previous owner actually overtightened these as there were tiny bits of ‘minced’ plastic visible as if the brass sockets have rotated quite a bit.

Membrane blanket

Right beneath the frame is the membrane blanket (again like most Model Ms), a mat of rubberised material used to dampen the stress from repeated strikes from an actuator on the membrane assembly. A Unicomp employee (Troy Fletcher) who frequents my Discord server has mentioned a Model M without a blanket cannot reach their rated lifetime.

Membrane assembly

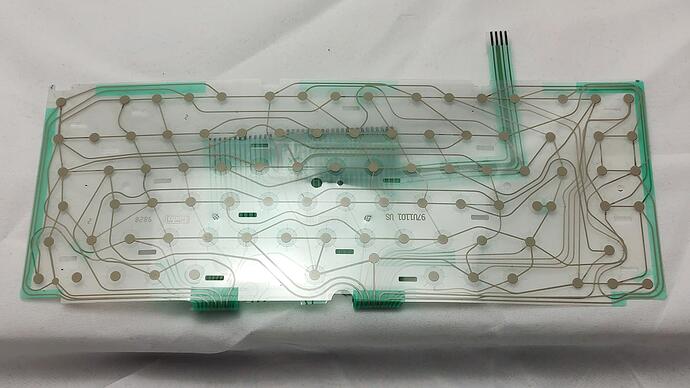

Now we get to the membranes. There’s not much to comment on, it’s just the medium for the keymatrix and various contact points to be pushed together. This one was made by Goda Technology Co. Ltd. from Taiwan.

A potential future issue is the visible ‘kinks’ in these flexible flat cables. The keyboard actually works fine as-is, but if matrix columns or rows stopped registering, these would be the reasons why. They could be patched with conductive ink and maybe some solid material placed behind a break to keep it straight.

Base plate

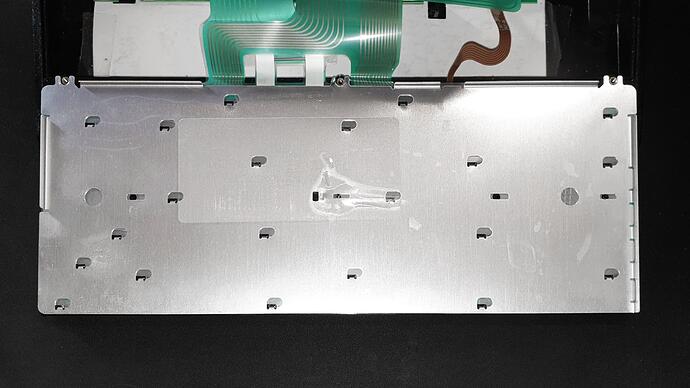

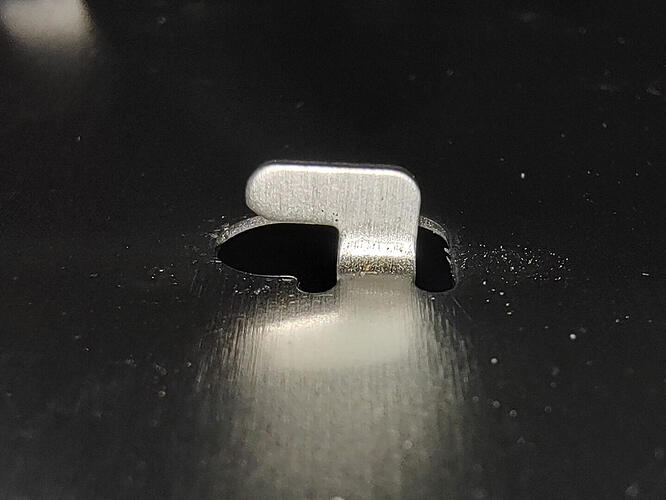

Right at the bottom of the assembly is the plate that keeps it all together. On Model Ms, you expect plastic rivets that might break with age. Here with the keyboards, we have hooks that allow us to non-destructively open M4/M4-1 keyboard assemblies (M4/M4-1 numpads still use plastic rivets). This is what a ‘healthy’ base plate looks like:

This part also seemed to have been mishandled as there were bends and dents throughout. It looks like someone tried to pull the base plate off without actually trying to unhook it, so some hooks near a corner were bent where someone presumably tried prying the plate off and they needed realigning before I could actually slide the thing off. I managed to overall straighten the plate out so all keys press consistently but there are still some dents. I think I need a soft, rubber mallet to carefully undo these dents.

To actually unhook a M4/M4-1 base plate, you need to push down on this sloped plastic part near the centre and then the plate should slide off.

Whilst straightening the base plate and applying preventative measures to the membrane are potential future works, the keyboard works for now. So now onto restoring the outside, a future update!