I put a Novel Keys Blueberry stem in a YOK Trash Panda housing and I really like the feel and sound of it. The problem is that the actuation point is all the way at the bottom, meaning you have to bottom out in order to actuate the switch. The switch feels and sounds nice, but since the actuation is right at the bottom it kind of defeats the advantage that mechanical keyboards had over membrane keyboards(actuation in the middle vs at the bottom). What are your thoughts and opinions on this?

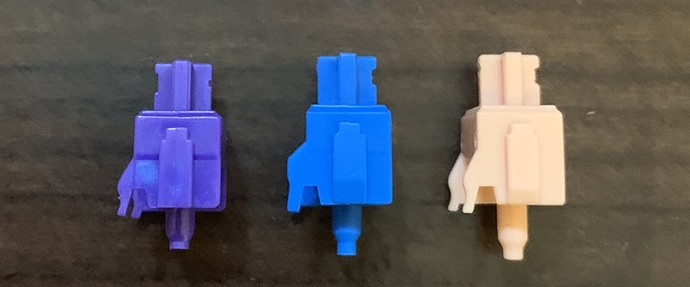

Ahoy! I think the experimentation is useful even if the combination itself isn’t ideal. While I don’t think bottoming-out is intrinsically bad, it looks like the tactile event and actuation are very separate with this combination. To borrow an image from this post, here’s the Blueberry stem next to a couple other strong tactiles:

I believe that’s a Zealio, the Bb, and a Halo stem.

If we draw an imaginary line from, say, half-way up the top slope of the tactile legs of the two outer stems (roughly where actuation happens for those), they’re very close together. However, the Blueberry’s top slope is that little tiny 45-degree thing way up there.

I’ve not used stock Bb’s myself, but I think actuation is intended to happen just after that sharp angle starts. For this combo, it looks to be happening farther down on that 45-degree slope.

IMO, this combo isn’t ideal because the first tactile event the user feels doesn’t appear to be connected to actuation - but I do think it’s worth noting the feel if you like it.

I’d encourage experimentation with other housings, but I also think there are some things you can try with the Trash Pandas.

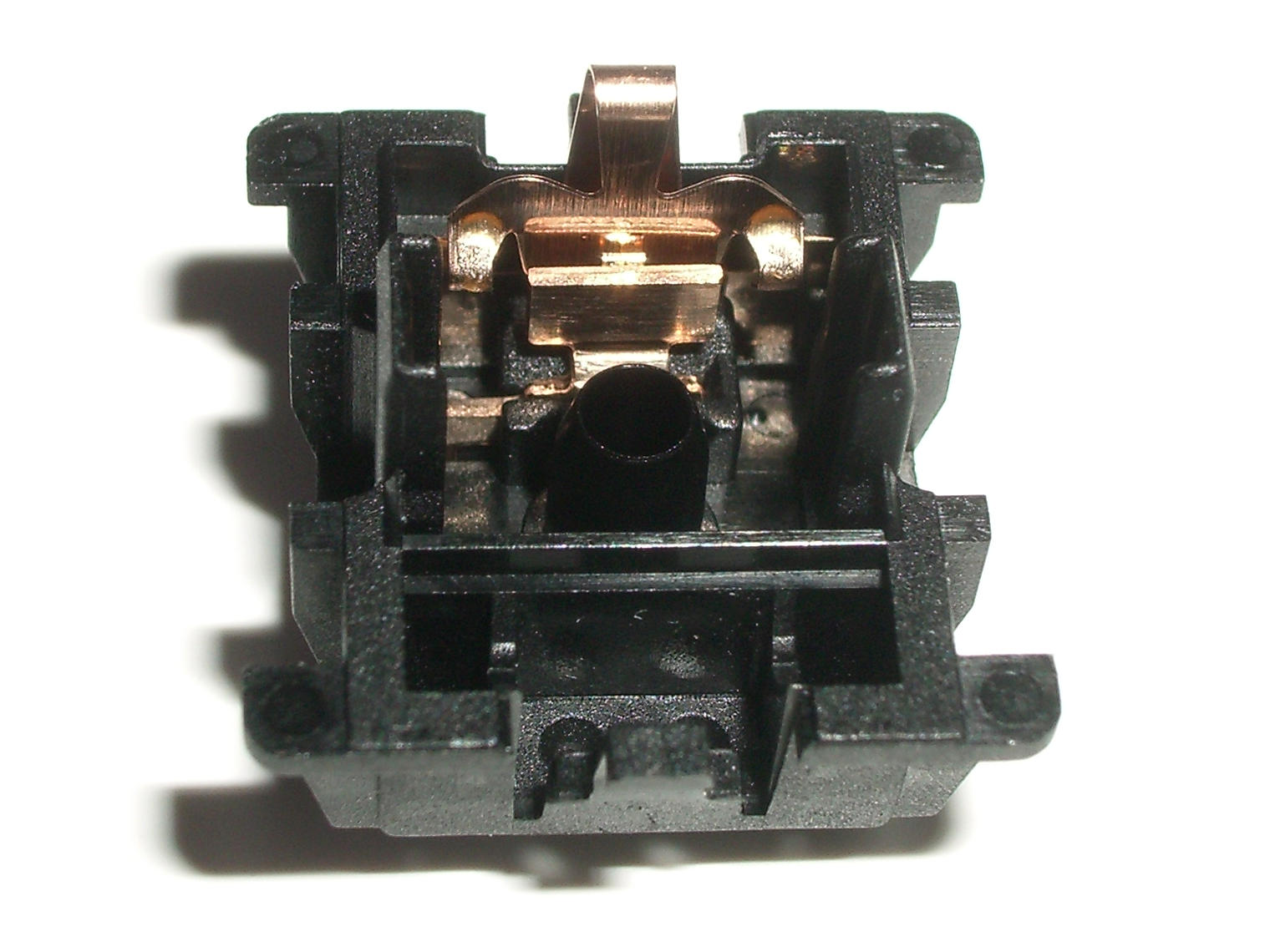

There may be ways to modify the housing to actuate sooner, or possibly even swap the leaves from the YOKs into some other housing that has the stationary contact farther forward - not sure how easily those will let go of their leaves, though.

Another probably un-tested thought - and this would also be tedious but should work and be possible to do with some consistency; wrapping the stationary contact (thicker one) with tin-foil, one layer at a time, taking care to flatten it against the active surface. In theory, each layer would reduce how far back the moving contacts would have to go to close the circuit.

By one method or another, if you could get it just to the point where the switch reliably actuates close enough to some part of the tactile event, I think you’d have a solid (if possibly labor-initensive) frankenswitch on your hands.