Build #34: Austin

I still have far too many work surfaces in my house that don’t have a CP-style board. So, how about we keep the big board party going? Hot on the heels of the HBCP, the Austin from Drift Mechanics arrived

on my doorstep, and although my build backlog keeps growing, I couldn’t resist doing this build now as a nice counterpoint to the HBCP.

If you’re a regular reader of these build logs, you know that my tastes run to tactile switches, and generally speaking, I’m fine with assertive tactility (Holy Pandas or 78g V2 Zealios, anyone)? But, after what feels like a lot of builds with loud, heavy, clacky switches, I wanted to dial things back a bit, and I’ve had the impression that a stock Halo Clear might offer a more moderate tactile experience without sacrificing too much of the sound that I enjoy.

So, rather than sacrifice more Halos to the HP gods, I decided to give Halo Clears a shot for this build. To allow for more direct comparison with switches I know well, I used what has become my default tactile lubing approach these days: tub-lubing springs with 104, and stem lubing with 3204. I’ve reached the point where I don’t bother lubing the switch housings; I’ll instead make sure to lube the “rail” around the top of the stem, where the stem makes contact with the housing. With that approach, enough lube gets transferred to take the slightest edge off of the clack without dramatically affecting sound. Let’s get to the build!

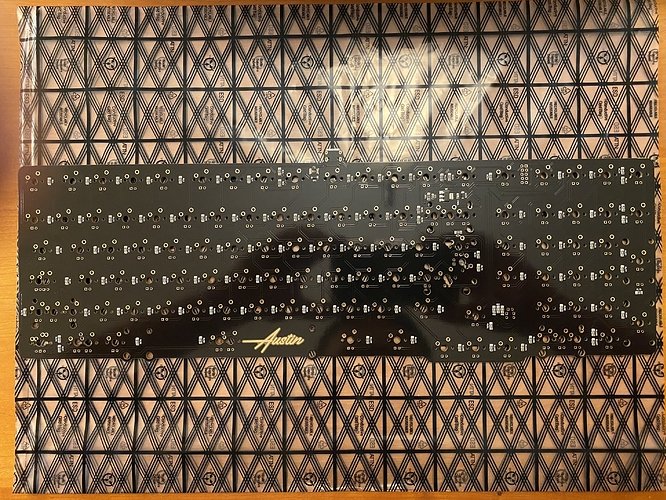

The Austin PCB uses an ARM STM32F072, it’s relatively free of swiss cheese, and it offers ESD protection, which is very much appreciated by those of us who live in dry climates, particularly during the winter months. Looking at the top of the PCB, the finish is somewhere between shiny and matte black; enough reflection to see me taking potato pics, but that’s about it. To my eye, the Austin logo is tastefully done here. Note that the PCB also ships in a nice ESD bag, which it’s resting on in this photo.

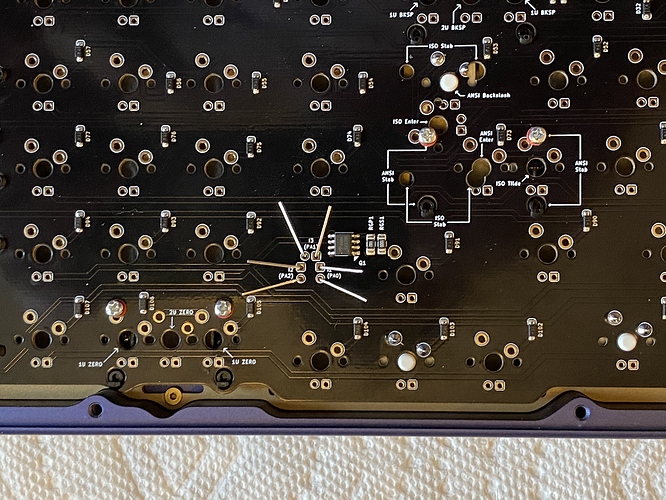

The reset button is located on the underside of the PCB, just above the numpad cluster, not too far from the ARM chip. This means we’ll want to flash the board to our desired keymap before we close up the case.

Getting prepped for stab time. Eating into my stash of good GMK screw-in stabs, and pulling out some cloth washers just in case.

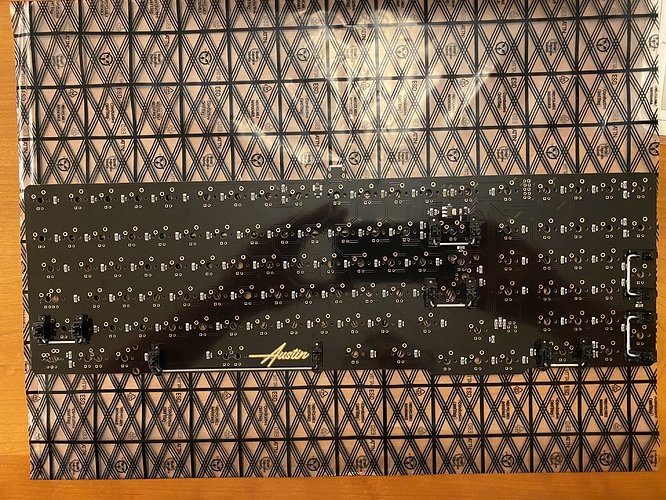

After clipping, lubing, and installing, here’s the top side of the PCB.

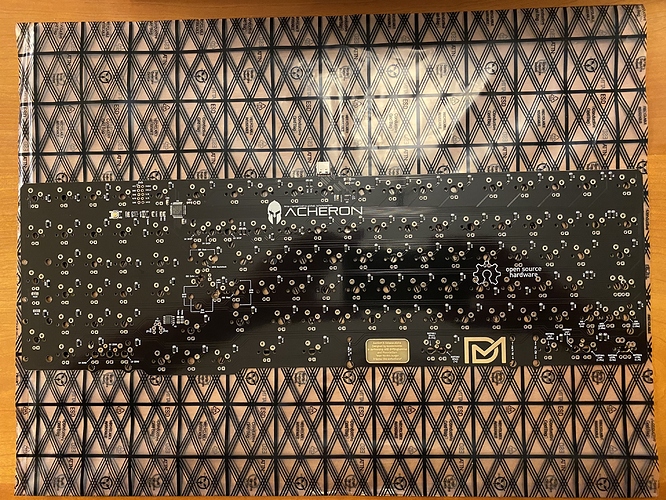

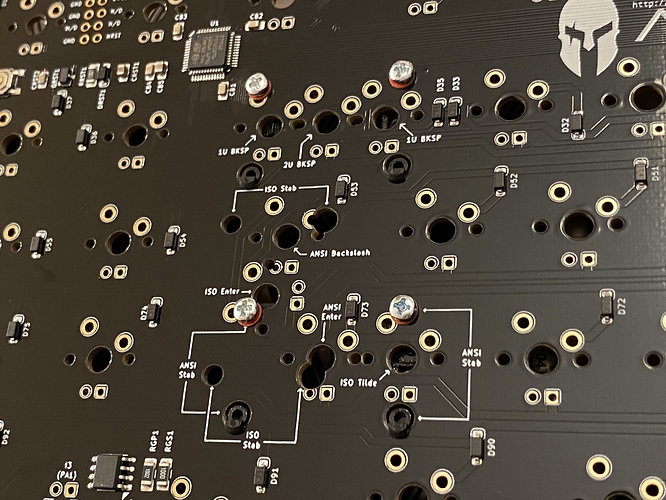

Looking at the underside of the PCB, we get a good look at a nice feature of this PCB - where multiple stab holes are present, text markings tell you which holes correspond to various layouts. For new builders, this can be very helpful, and even for seasoned builders, it’s a convenient touch. I’m somewhat surprised this hasn’t become a more common feature for PCBs that support multiple layouts.

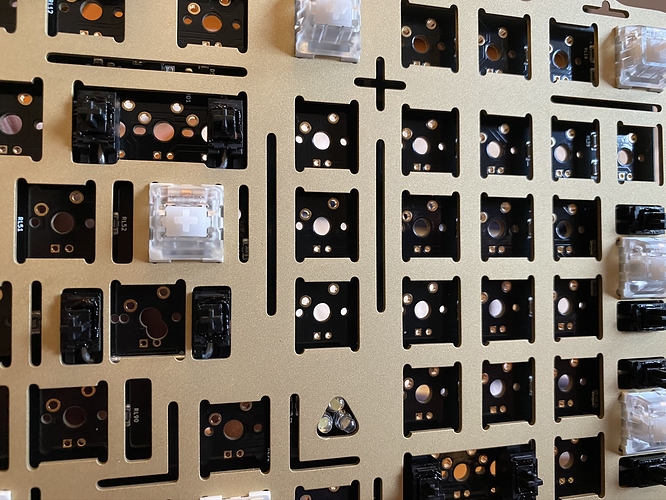

Before we proceed further, let’s take our first good look at the Austin case and the sandblasted brass plate, as well as what is arguably its main distinguishing feature visually and functionally - an additional column of keys between the numpad and the rest of the board. A triangular group of LEDs sits directly under the logo on the top of the case, which has holes to allow light to shine through.

The underside of the case features a brass weight, with engraved Austin branding. The top and bottom of the case are held together by six screws. The finish on the weight and the case is quite good - it’s an A-stock board, and it looks the part.

Bumpon time - nice, snug fit.

Taking apart the case, we now have a better look at the base. It’s a triangular slab of aluminum, with the weight mounted by screws on the interior base. The brass weight is also engraved with the Drift Mechanics logo.

Looking at the underside of the case top, we see that the plate is top-mounted with eight screws - five along the top edge, and three along the bottom. We also see a triangular cutout to make room for the Num Lock, Caps Lock, and Scroll Lock (NCS) indicator LEDs.

Zooming in closely, we’re going to need to think a bit about installing the NCS LEDs. To prevent light bleed between the LEDs, they’ll sit inside recessed areas, with light shining up through the pinholes.

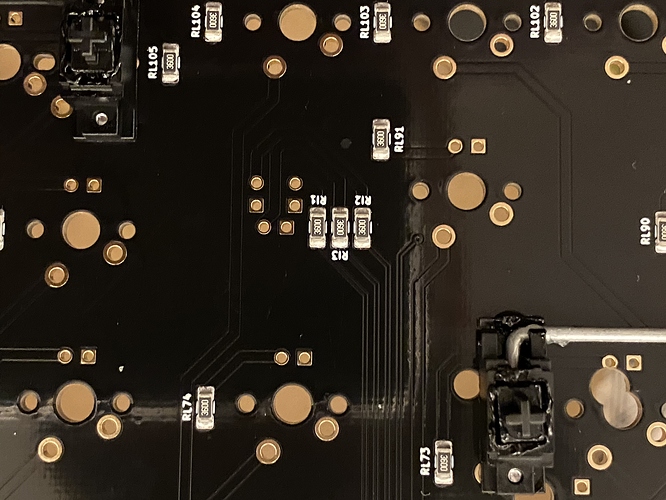

On the PCB, the pads for the NCS LEDs are equidistant from the Enter and numpad 0 stabs (right next to the RI1, RI2, and RI3 SMD components in the center of the photo).

To help ensure good LED placement, I first mounted and soldered a few switches to get the plate and PCB properly positioned into relation to each other. Then, I threaded the LEDs through the hole in the top of the plate, into the PCB pads.

LEDs have to be mounted in the correct orientation to function properly, and up until a few boards ago, I thought there was a convention for this - the long lead of the LED goes through the PCB hole with the square pad. However, I’ve run into a few boards recently for which the LED orientation worked the other way - specifically, long lead of the LED through the circular pad. As a result, I no longer think there is a convention, or if there is, it’s not one that has general agreement, so I test.

If you’ve never tested, this is where it comes in quite handy to have one keyboard with NCS keys already plugged in. Plug in the PCB using another USB cable, hold the LED so that its leads make contact with one pair of pads, and use the keyboard to trigger num lock, caps lock, and scroll lock. If the LED doesn’t light up, switch the leads and try again. Sure enough, here’s another exception to “the rule”: for the Austin, it’s long lead through circular hole.

I found that you have to work the LEDs around a bit before you feel them “fall” into the recessed holes in the case top. Be sure that you have all three seated to the same height before you solder - one of mine wasn’t quite all the way in, but so it goes. Once you’re happy with their placement, it helps to fold the leads over to keep the LEDs in place prior to soldering.

At this point, we can solder the LEDs in place, cut the excess lead lengths, and mount and solder all of the remaining switches.

The Austin ships with O-rings for top-mounting the plate. However, there aren’t recessed cutouts in the case top for the O-rings, which makes installation a bit trickier. We can see this in the following photo.

Do you have tweezers? Get a pair! Here, we can manually position the O-rings and gently place the plate on top, and then use the tweezers to fine-tune the positioning of the O-rings before we put in the top mount screws, saving a lot of trial-and-error to get everything properly seated. With that work done, the top of the case is ready to go.

However, now is the time to remember that the hard reset button won’t be accessible once we put the case together, which means now is also the time to put together a .bin (ARM, remember?) and flash it. The Austin has a stock keymap out of the box, but the Austin PCB is not yet in the main QMK repo, and the code is undergoing some work to make the Austin VIA-ready. However, Gondolindrim’s repo is available in the meantime if you’re one of those people that can hack QMK code and want to get customized straightaway.

I’m one of those people, so I went ahead and grabbed a snapshot of Gondo’s repo and went to work. This was pretty straightforward; the only problem I encountered involved the LAYOUT macros in QMK.

Remember that deep under the hood, a keyboard is physically laid out as a perfectly rectangular logical grid called the scan matrix. Each keypress corresponds to a specific (row, col) coordinate on this matrix, determined by the physical connections to pins on the microcontroller. Since the scan matrix almost never corresponds directly to the actual physical layout of the board (except, perhaps, for ortho boards), you can write a LAYOUT macro which converts between the physical layout and the scan matrix layout - once you’ve done this, you no longer have to think in terms of the scan matrix, and can instead assign key functions to locations in the physical layout.

Why was any of this a problem? Well, the Austin only offers one LAYOUT macro at present, which is a one-to-one mapping from the scan matrix to the physical layout - in other words, the simplification you might normally expect from the LAYOUT macro isn’t present. I noticed this when I first started working on the code, but somewhere along the way I forgot, and on my first flash attempt, the top row of the numpad got garbled. After staring at the code for a while, I finally remembered that the existing LAYOUT macro was just a passthrough for the scan matrix when I noticed that the scan matrix was 19x6 (hence 19 keys per row) - but R1 has 20 columns (with split backspace). Aha! Turns out numpad minus, up on R1 of the physical layout, is down on R5 of the scan matrix. From there, it took all of one minute to fix and flash, and I’m back in business with all of my favorite keybindings.

We’re now ready to screw the two case halves together, at which point we’re ready for keycaps!

So, first impressions? The Austin is a solid, premium board. The ano is uniform and smooth, and the sandblasted brass shares the same properties; the overall finishing is very good. The Austin has significant mass, and that translates to an even, consistent sound. The layout is interesting - for those of you that want a few more nav keys than a CP offers without going completely fullsize, this is for you, and you’ll be implementing it on a quality PCB. It has been a good few months for 1800 and CP fans - the HBCP, the EXT65 (which, despite its name and the absence of an F-row, I treat as a member of the same functional layout class as a CP), and now the Austin.

Lessons learned

-

Coming from 78g V2 Zealios, stock Halos (to my ear) offer a crisper, slightly deeper sound. The tactility is almost progressive, in the sense that if you’re a light typist, it’s almost not there, but under more aggressive typing, the tactility pushes back more. Overall, I think a Halo Clear is a decent option for those you that want more moderate tactility, but overall, I thought V1 Zealios did a better job filling that slot in the switch market. YMMV.

-

If you’re a QMK user that likes to code up your board’s features, take a good long moment to review your board’s LAYOUT macros before using them, especially if only one macro is available, and especially if you’re working with a large board - the scan matrix location for a key may be quite far away from its physical location.

-

I would have liked the recessed cutouts for O-rings and a top-mounted PCB reset button here, as on the HBCP; on the other hand, PCB markings to help avoid switch and stabilizer placement mistakes are always welcome, and they’re done well on the Austin. Are any of these things show-stoppers, or even anything that’s going to be a real issue when the build is done? Of course not. But as I work on more and more builds, it’s the little details that catch my attention.

-

A good pair of tweezers: once again, a builder’s best friend.

-

Once again, the value of taking the time to look over all of your components and think through the build, before building, should not be underestimated. The NCS LED installation wasn’t difficult, but it would have been more painful if I hadn’t taken the time to see how the plate, PCB, LEDs, and top case were all going to fit together. Just a little reminder to my future self.

And, with the Austin R2 entering IC, perhaps a little reminder for your future self?

Specifications

case: Austin

- cobalt blue anodized 6063 aluminum

- sandblasted brass weight

case dampening: top-mount O-rings

PCB: Acheron Austin

plate: sandblasted brass

plate/PCB dampening: n/a (relief cuts)

stabilizers: GMK PCB screw-in

- 1x6.25u, 6x2u

stabilizer mods:

- clipped and lubed with SuperLube

- installed with cloth washers

switches: 102x Halo Clears

switch mods:

- springs tub-lubed with Krytox GPL 104

- stems hand-lubed with Tribosys 3204

- no housing lube

keycaps: GMK Solarized Penumbra

HxWxD (without caps or feet): 1.31" x 16.13" x 5.5"

HxWxD (without caps): 1.38" x 16.13" x 5.5"

HxWxD: 1.63" x 16.13" x 5.5"

assembled weight: 3.36 kg (7.41 lb)