Recently I have been slowing waaay down on my builds and really trying to pay attention to each piece of my build and how to understand it’s function and if there is any way to help it perform more efficiently or smoothly.

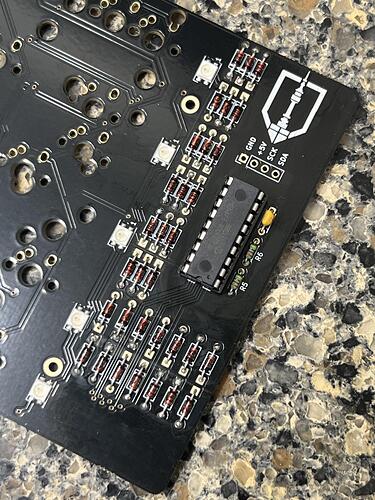

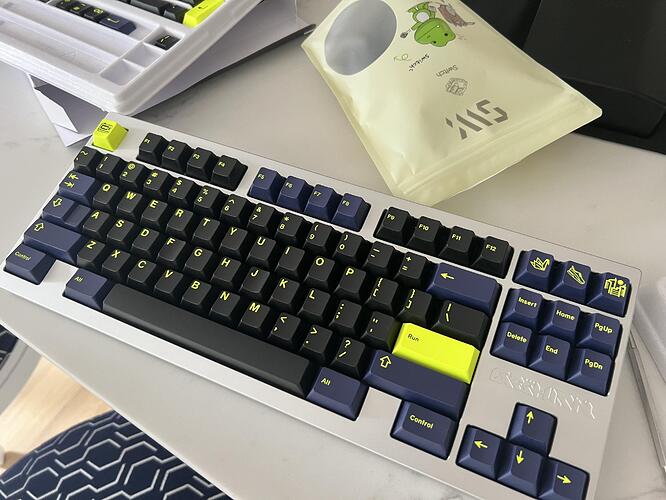

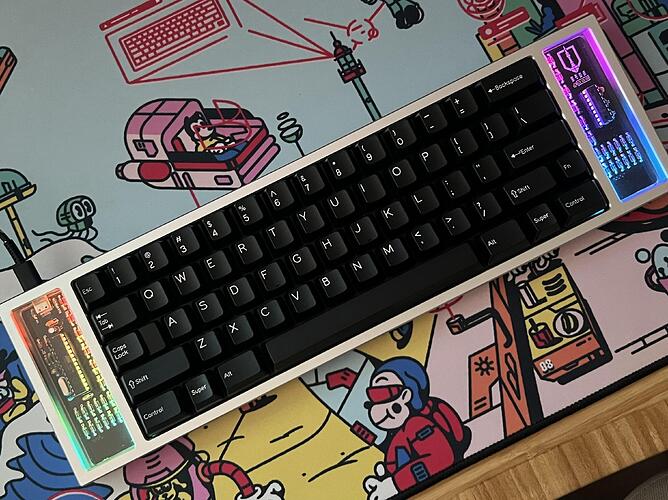

No build has been more enlightening than the Class60 for me as this has been my first electro-capacitive keyboard build.

While it comes with everything I need to build it from the factory, I am not really one to leave things as stock. While waiting for it to be delivered, I went down the internet rabbit hole a bit as to upgrade, or standard mods for EC or Topre boards as well as how I can apply that to what I already do to my own MX style builds.

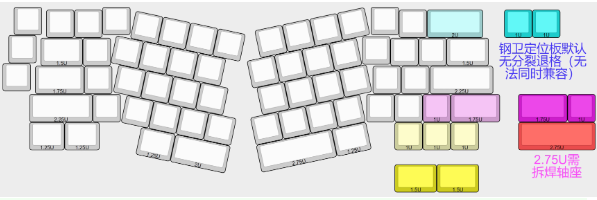

Right away is the fact that this build allows for MX-style plate mount stabilizers, so I decided that this would’ve a great chance to try out the third iteration of TX’s AP stabs in their plate mount form.

I am really coming around to the fact that these come from the factory with some of the best clearances I have seen so far and seem to benefit the most from my light improvements of sanding down the moulding lines and also finish rounding and polishing out the ends of the stabilizer wires.

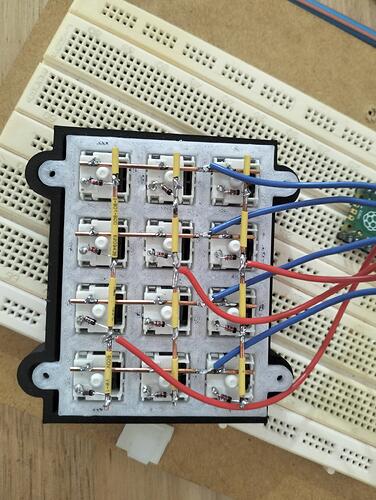

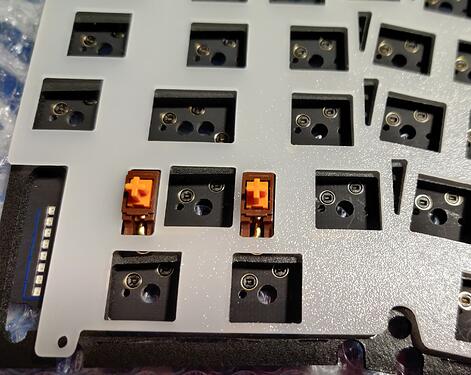

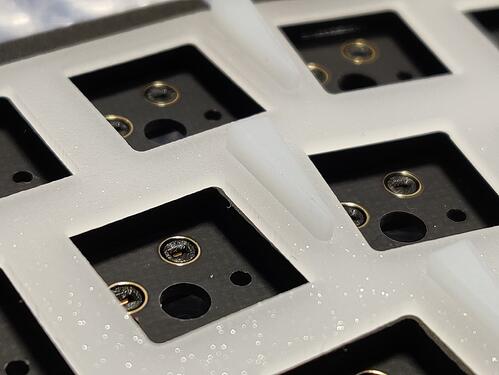

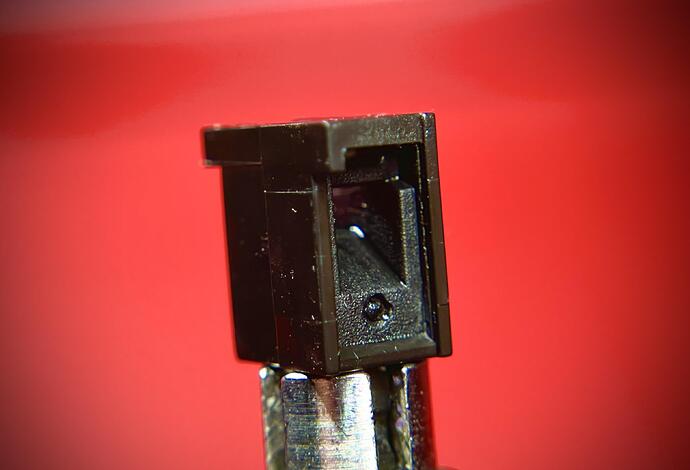

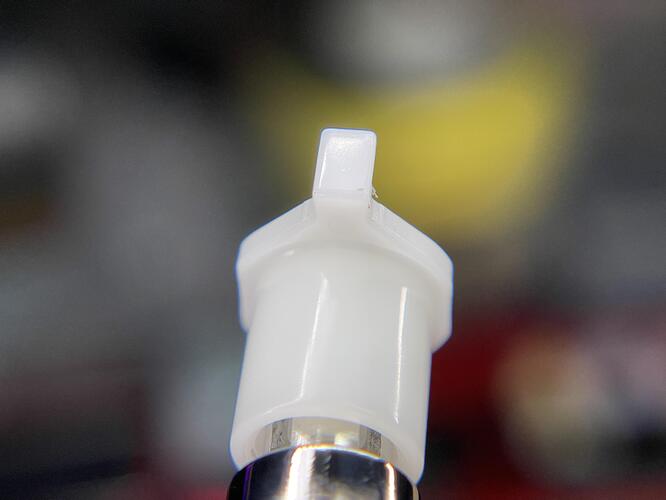

With this being my first time working with the slider/housing combo of an EC build, it appears that lots of folks really seem to have issues with how smooth the sliders and the housing works together, so I decided to go all in and polish the stems and sliders that came with my kit. I have been in the hobby of polishing and detailing cars for over a decade so I have more polishes, compounds, waxes, coatings, etc than should be allowed, but decided to try out some of my tried and true plastic polishing techniques towards this hobby.

With my trusty HOTO rotary tool and some cotton and wool polishing wheels, I decided to use my one-two combo of Meguires M105 and M205 to cut and polish the sliders and housings and so far have seen pretty good results.

Yes, it is time consuming and tedious, but I am of a mind of trying to perfect it the first time so I don’t spend too much time “what if-ing” it after it’s built.

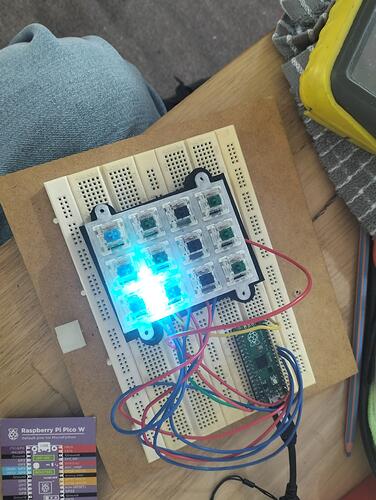

The sliders have so far come out really well with just the cutting pass…

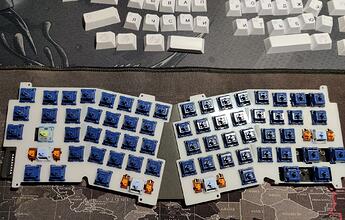

Before:

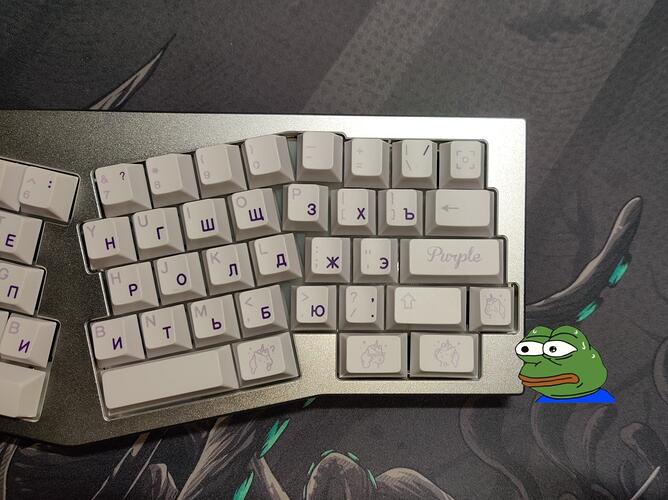

After:

While it doesn’t seem like much, once these are polished and lubed, these babies are going to transcend buttery-smooth…

Next steps are polishing and then giving them a bath in the ultrasonic cleaner. Then they go for a few coats of dry lube before one very thin coat of Carbon GS1 of them as well as the housings (which received the same cut/polish treatment of the stem hole).

I will try to keep you guys posted as I go, but work has been making movement on this build very slow going, not to mention sourcing and waiting for some of the other aftermarket parts I orders for upgrades…