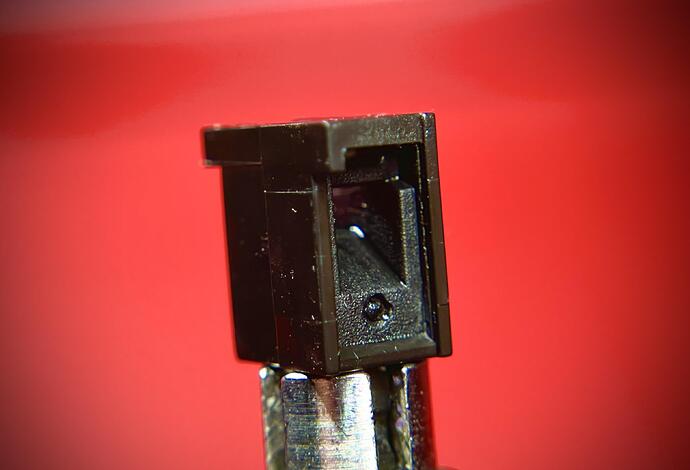

chef’s kiss very satisfying handwiring.

Thanks. I always like to get one pic before the MCU with 20+ wires latches on like something from the Borg or the Matrix. ![]()

Trying to mess around on a project that won’t cost me much more than time. I bought some screws and matching RAL paints for my HMKB cases. Going to try and paint a set to color match the cases.

Pretty good for one coat, but I think I’ll have to paint inside the socket with a brush first. Also, I dropped the freshly painted screw on the wet driveway. lol.

I’m not sure if I prefer the painted screw. I’ve always like the industrial look of the stark black screws on the metal cases. However, I’m going to try to see it through with a fully painted set. First, I have to wait until it stops raining. Also, because it’s in plain view, I’ll have to get a good process to ensure a nice finish. (Unlike the “dropped on the wet driveway” look)

If you are customising your fasteners, another thing you might consider is alternative screw heads. Pan head and button head are about the nicest standard heads (as in DIN / ISO) but I like to use wafer heads, which seem to be relatively common but not specified by the usual standards. So they tend not to be findable from european suppliers (at least, not by me) so I get them from China via Amazon or Aliexpress. The magic search phrase is “ultra thin super low flat wafer head” (sometimes without the “low”).

I think something like this would look very “industrial”, although they might not feel so nice, especially those below the bottom row.

Or, if you wanted to make it require a less common driver:

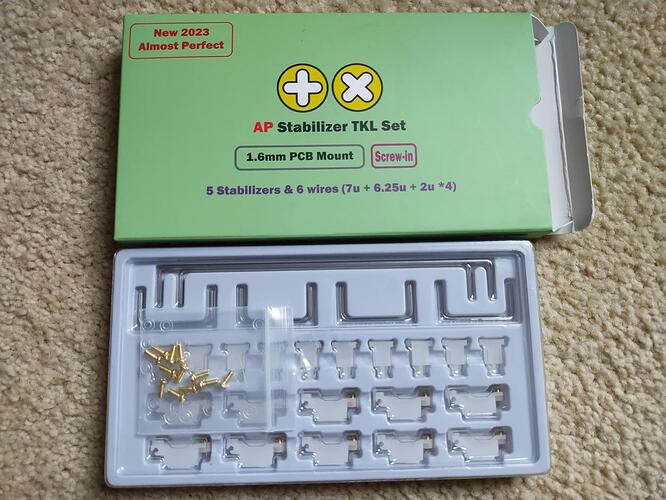

Decided to finally try out TX’s AP (“Almost Perfect”) stabilizers. Seeing as how I am a Cherry clip-in fan, I decided to give TX’s new screw-in version a shot.

I have used TX stabilizers before, but in their previous version (V3). I gave the 1.6mm, 1.2mm, and long-pole variants of both a shot and found them all to be no better or worse than other stabilizers I had used in the past, aside from being better for o-ring mount keyboards due to the lack of a threaded insert housing.

TX’s V3 stabilizers apparently had issues with ticking and stems getting stuck in their housings. The new AP versions of their stabilizers is supposed to fix all of the previous issues and be their best stabilizer yet by rounding out some of the edges, and thickening the housing to reduce stem wobble.

I am aware of a percentage of folks in this hobby that are looking for the “easiest” build experience as possible so they are constantly looking for switches that are perfectly lubed from the factory, stabilizer wires that are completely straight out of the box, and keyboards that show up right away in VIA. While all of those are something companies are looking to achieve with current offerings, I am someone who tries to always make them better. Nothing is ever “perfect.” TX’s claims that these are Almost Perfect had my B.S. Meter fully pegged…

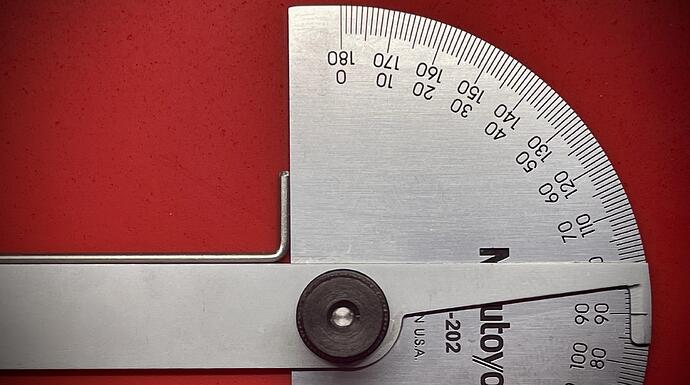

I was pleasantly surprised to find that the wires were were almost straight right out of the box and their 90-degree bends were actually 90-degrees. Not bad…

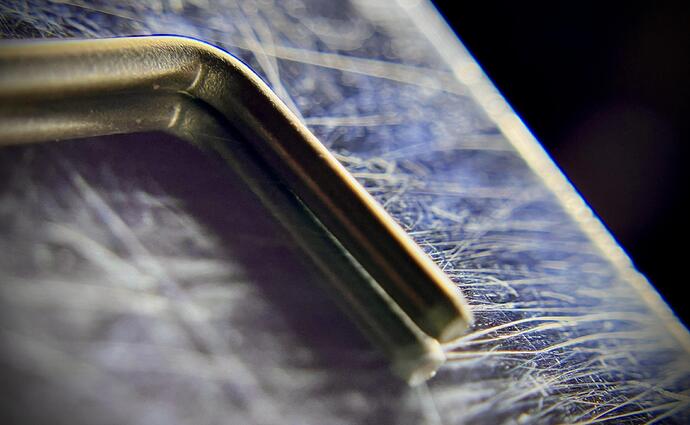

I did notice that they also attempted to taper the edges, which is something I picked up from :3ildcat and believe goes a long way towards smoothing out stabilizers, but TX sort of half-assed it by not rounding off it edges or using a less aggressive grit to taper the ends…

Since I was already prepared to do so, I went and finished up their attempt, making it more deserving of the “Almost Perfect” title.

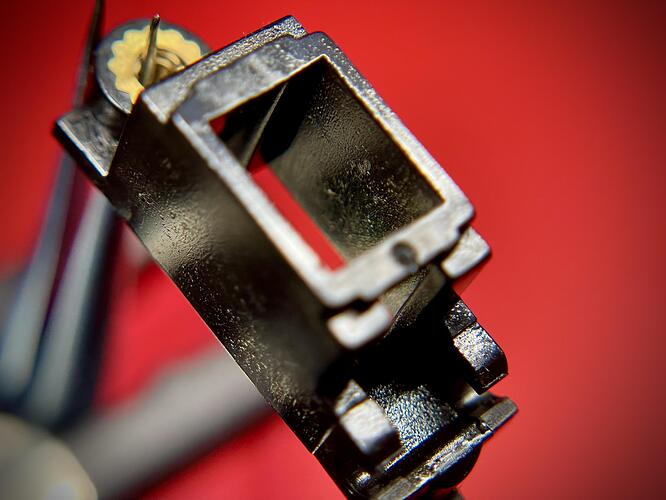

Their housings did appear thicker than I remember, and while not completely polished, still relatively smooth.

The stems themselves also seemed pretty beefy, and seemed to really narrow down the room to the wire has to move around in to account for thicker wires or excess lube.

Due to these tighter tolerances, I would avoid using thicker lube or grease on your wires, and would probably not go any higher than GPL206 or Carbon GS3 for the wires and a thin coat of GPL205g0 or Carbon GS2 for the housings and stems.

All in all, I would say that if you are in need of a good screw-in stabilizer, and these are on sale, TX’s AP stabilizers are Adequately Passable. ![]()

See this is where I think NyoGel comes in handy. It’s very thick and sticky, but you can apply it in a thinner coat than any other substance I’ve found.

To pick an analog from the keyboard hobby, it’s comparable to powder coat and cerakote. Both cover the material and do the job, but one is significantly thinner.

And the bigger issue I’ve had lately with greases like superlube and dielectric is when they overflow the cavity and get under the stabilizer stem and rest on the PCB. I’ve now found 3 boards where this has happened. I found them because I couldn’t figure out why the stabilized key felt wrong. Turns out, it was momentarily sticking at the bottom of the keypress because the dielectric grease had spilled out. Luckily, these were hotswap boards. I feel like the NyoGel wouldn’t be able to goop out the same way.

@pixelpusher , There are different grades/types of nyogel. What type do you recommend?

760g

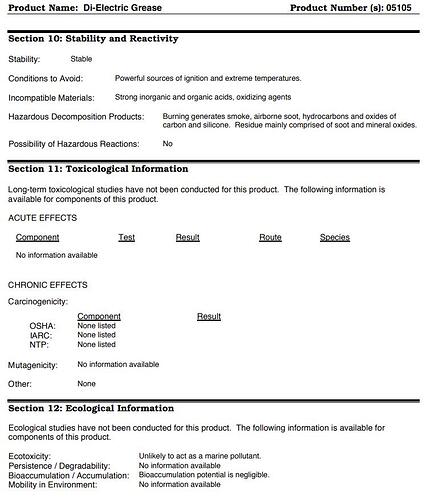

I recommend that you read the NyoGel 760G safety data sheet:

I am a huge fan of Nyogel, myself, and typically use it for my stabilizers, I feel like what makes it great would be a little detrimental with these stabilizers due to the restriction of area for the wire.

I absolutely love Nyogel for it’s ability to keep the wire from jumping around in looser stabilizers, and prefer it over XHT-BDZ because of it’s cleaner appearance and cost, but with lighter wires and tighter spaces, I feel something a little less viscous than Nyogel.

I have only used Nyogel 767A, so that is where my bias lies. I am also a fan of Loctite’s dielectric as it stays put and (from what I can tell) won’t stain your PCBs or separate over time.

Yes, I keep forgetting things like this.

It’s a category 2 warning chemical for reproductive toxicity. This means:

“Evidence from animal and/or human studies is limited”

And that the manufacturer should state:

“Suspected of damaging fertility or the unborn child” and you should “wear gloves” when handling (as required to state by federal regulation.

I have worn gloves and work with disposable surfaces for lube for quite some time. I think it was actually after Krelbit had a comeapart from seeing a certain kb enthusiast using his hand as a palette for applying lube to switches. (where did @Walkerstop go, anyway?)

If you’ve ever lubed stabilizers or switches on a dark surface, you can see just how persistent things like Kryotox or HTX-BDZ can be. The only way I’ve ever found to remove them is with 99% ipa and a lot of scrubbing from a microfiber cloth. But I started to wonder if I wasn’t just spreading it thinner.

The way I lubricate my stabilizers, the excess lube on surfaces is always 205g0 and never grease. But still, working with gloves and a disposable work surface helps cleanup a lot.

I need to make a video some day of my process. It’s very fast, very easy, mess free, and nearly always effective for noise-free stabilizers. The key is to find where you make messes and mistakes and create a workflow that won’t allow them to happen in the future. I haven’t found a perfect way to eliminate the 205g0 from getting on work surfaces yet, but I’m close. My process is methodical. Same exact way every time. Even down to where I place items on the work bench throughout the process.

I’m in my own bubble and don’t think about such things. I’m a married, 47 year old man with one child and no intention on further reproduction. But this is something important to consider and warn everyone about. Same thing goes with lead exposure while soldering, as well as exposure to fumes from burning flux.

And of lot of this is certainly related to increased exposure. I imagine that some people only build a keyboard or two in their lifetimes. But some people build them for a living. These warnings are more poignant for the latter. (Or, if you are weird like me and just build hundreds of them for fun)

I recently bought the same stabs, except mine are white, but that shouldn’t make a difference, right?

I haven’t had the chance to install them yet, but I did quickly check the wires. They all seem very straight, when checking against the screen of a smartphone. However, I noticed that none of my wires have the same sort of taper as seen in @d3L7r0n’s photo. Here is a photo of mine (sorry for the poor camera quality):

It’s hard to see, but there does seem to be a very small 45 degree bevel around the edge, but it is certainly quite different than the higher angle taper seen in @d3L7r0n’s photo.

EDIT: oh wait, I should mention that mine should be the “long pole” version (according to what I ordered), but it doesn’t seem to indicate that anywhere on the packaging.

I still sand and polish mine, but I do that as to have one less thing to worry about.

I know that Staebies were different material between their different colors, but not sure about TX. I couldn’t tell the difference between the Staebies materials either, so not sure if it’s going to really make a difference.

@yeeb thanks. I like quiet stabilizers, but not enough to put people at risk. You never know who might stumble upon it.

Keep in mind that almost all other commonly used lubricants have similar warnings. I just looked into dielectric grease. It says always use gloves and avoid contact with skin.

and get this:

Like… they just haven’t ever done toxicological or ecological studies on it? WTH. ![]()

I would say if you are worried about noisey stabilizers and want to stay away from carcinogens, it might be best to look into food grade safe lubricants (that don’t erode plastic), or just have rattle. If going with the rattle, definitely stay away from Cherry or Durock stabilizers.

I also have tried Dow/DuPont Molykote HVG which I believe is food safe and even Kosher.

I find it to be a little more viscous that Nyogel 767A, but it will stay put and dampen the same.

As always, buy from a reputable distributor, and always take adequate safety precautions. Rubber/latex gloves are great at keeping fingerprints off of your build until you are finished as well, so I try to always keep a box on hand. ![]()

![]()

I didn’t get the HSA caps, but I tested with another set. I posted some findings here:

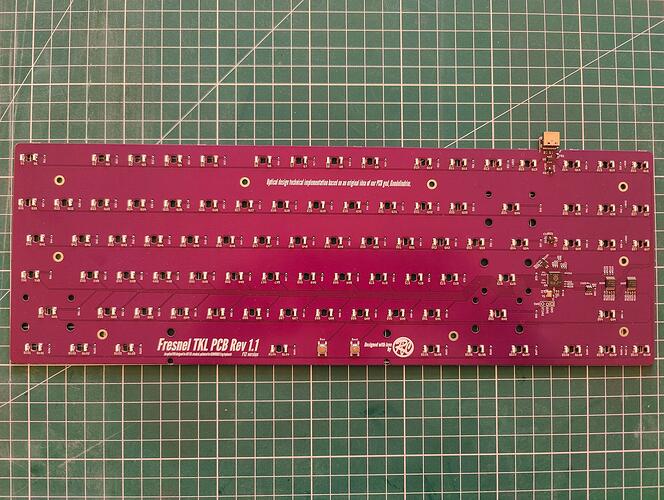

Frog build with Fresnel Rev 1.1 PCB today.

More details here: Fresnel TKL F12 PCB, an optical PCB for my Frog - #3 by Rico

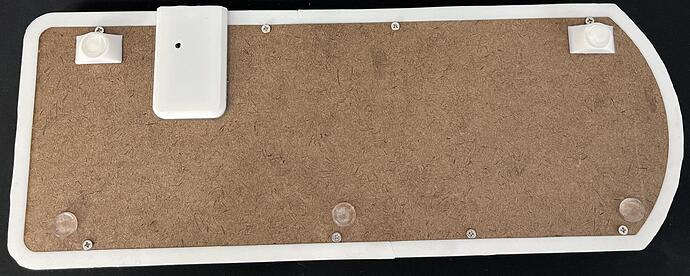

Finished the wiring on my 102-key no-stabs build. Closed it up before taking a final picture though, and I have no shorts so far so no immediate plans to open it back up. I used strands from an old cat6 patch cable to wire up the Pico. I erred on the side of slack and easy repairability with the mcu, so that part is not pretty,

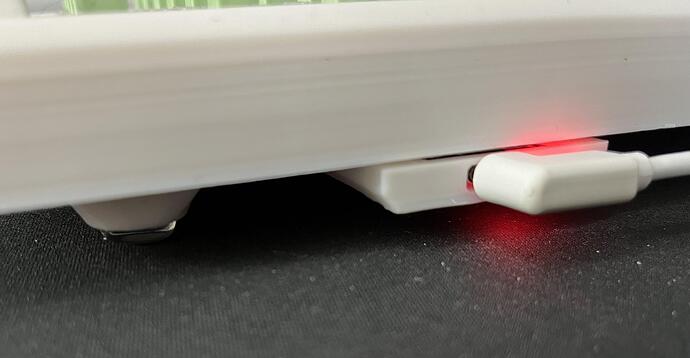

I was fairly pleased with the “blister caddy” for the MCU. The “YD RP-2040” fit right in after cutting a gap out of the bottom plate and using double sided gorilla tape to mount the print. The tape leaves a bit of a gap, but I can plug and unplug confidently, not always guaranteed on a handwire. I reprinted the stick-on feet from an earlier build after making sure they were taller than the caddy.

The final gap between the two printed halves is mildly annoying, but very livable. There is a bit of flex, certainly compared to aluminum plates, but I don’t think it’ll be too much at all and may fall into the “kinda nice” range. Printing a third back foot would also reduce it if that seems necessary. The box jades seem nice, but maybe one more clicky switch that fails to displace Box Navies. KMK programming went smoothly.

Nothing left to do now except get on with designing keycap legends.