So, I guess technically it doesn’t count as “workbench” yet, but I’m starting on my next cheap handwire board. I want to revisit DIY keycap legends, and I have my new jig ready to test with some blank white XDA (quite cheap in sets of 104), but it has been colder than a well-digger’s ass in the Klondike here in Texas, or else almost that cold but also raining. I don’t laser in the house, so I haven’t lasered at all.

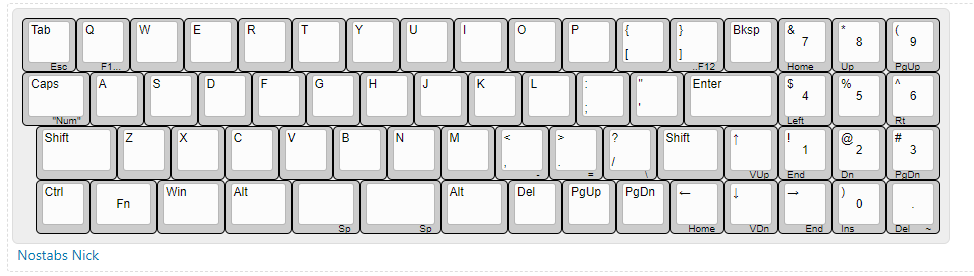

I am pretty sure I’m going for a no-stabilizers mini-1800 that doesn’t need a special keycap set beyond being unsculpted. I have been eating my own dog food for several weeks now with a couple of my boards, so I’m trying to learn what I actually like from that. I’m trying to design around the fact that I will likely never adjust to a split LShift, but I hate tuning and lubing stabs, AND I also like my boards, weird as they are, to bear some gentle nods in the direction of sanity. I have found that a split space with smaller keys is really not an issue, as I mostly land where I want with my thumb, the profile is not uncomfortable, and the debounce in KMK is good enough that an occasional slip doesn’t seem to trigger double presses. HERE is my first crack at a layout. I think it will be okay for simple data entry, but I’m struggling a bit with what to do with the dash and the equal/plus buttons. I suuuuupooooose I could just put the numrow on the top, but then we’re looking more at a slightly squished 65%, and that just seems less fun.

The plan for now is to do the plate in hardboard and 3D print a case in 2-4 pieces to go around it. Some of the techniques from my last build could be useful if refined a bit.

Switches will need to be generic red, harvested from a hotswap board, or… sigh… purchased.