This weekend I had two correlated objectives:

- Test if the switch matrix is working as intended, and try some workaround if not.

- Write a QMK firmware.

As with the first objective I encountered a quite a lot of problems.

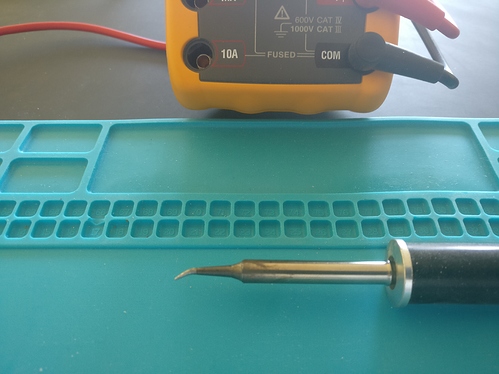

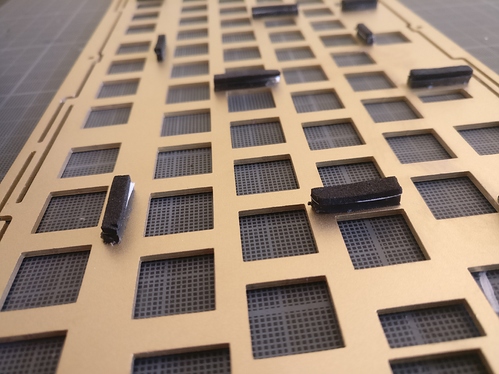

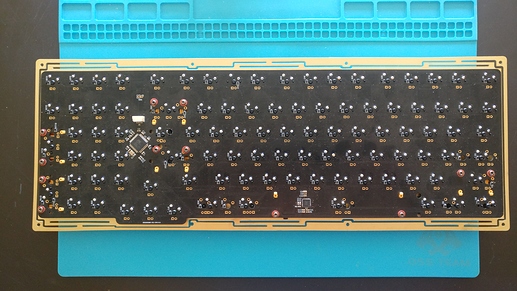

First, some diodes were not fully soldered and seven switches were not working as a result.

Had to track down every problem with a multimeter and resolder these diodes by hand.

The pads of these SOD323 diodes are extremely small and this made this task a challenge.

Next time I’ll either switch to a 603 footprint or SOD323 bigger footprints for hand soldering purposes.

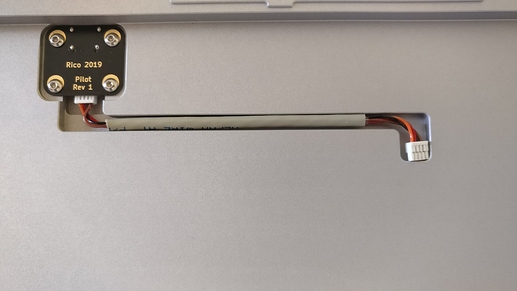

Second problem, the home made cable connecting the USB daughter board to the main board had a broken wire; depending on the orientation the wire was making contact to the header or not.

This drived me nuts …

Remember when I had trouble making the keyboard recognized last time? That was the reason ![]()

Re-attaching a new crimp to the wire and it was good to go.

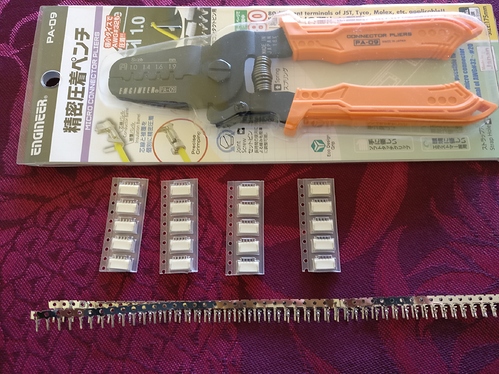

If you are curious, here is the hardware needed to do a JST cable yourself.

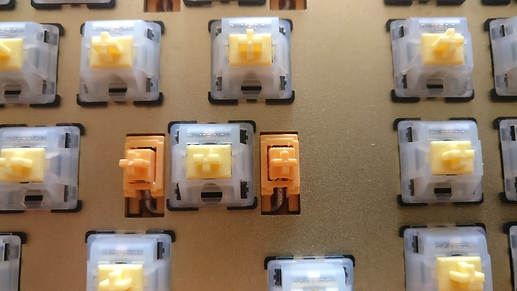

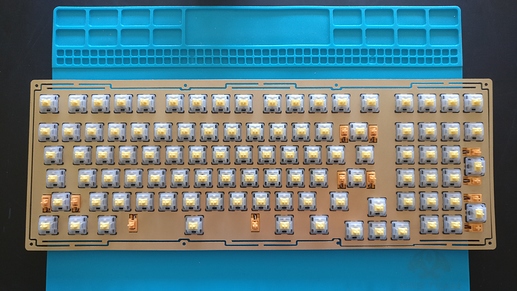

I could finally validate that the PCB was usable and it is a great news ![]()

Is it perfect ?

Certainly not:

- ‘O’ and ‘0’ footprints were inverted during placement on the PCB.

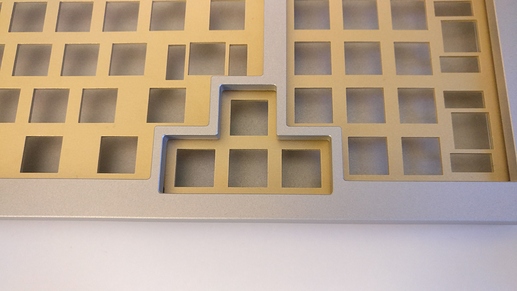

- Stepped Capslock footprint is placed wrong, I will have to do without…

- The 2 1U keys that can replace numpad + and enter are wired wrong, not a big deal.

Overall it could be much worse, having something unusable, and I’m happy of these results on the first revision of the PCB.

And now the QMK firmware.

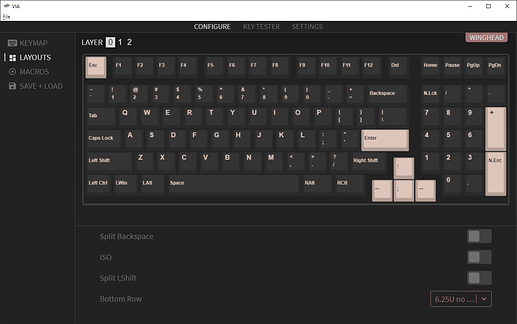

I wanted to try VIA as it can now be used without restrictions and what a great piece software!

It is very nice and easy to use, so much more convenient, a big thank you to @olivia and @Wilba and the others that I may have forgot !

If you want to port a keyboard to VIA, I strongly recommend the following links.

- VIA documentation, it explains everything including configuring QMK source code

https://caniusevia.com/docs/configuring_qmk - Have a look on @merlin great videos explaining how it does, it is very self-explanatory.

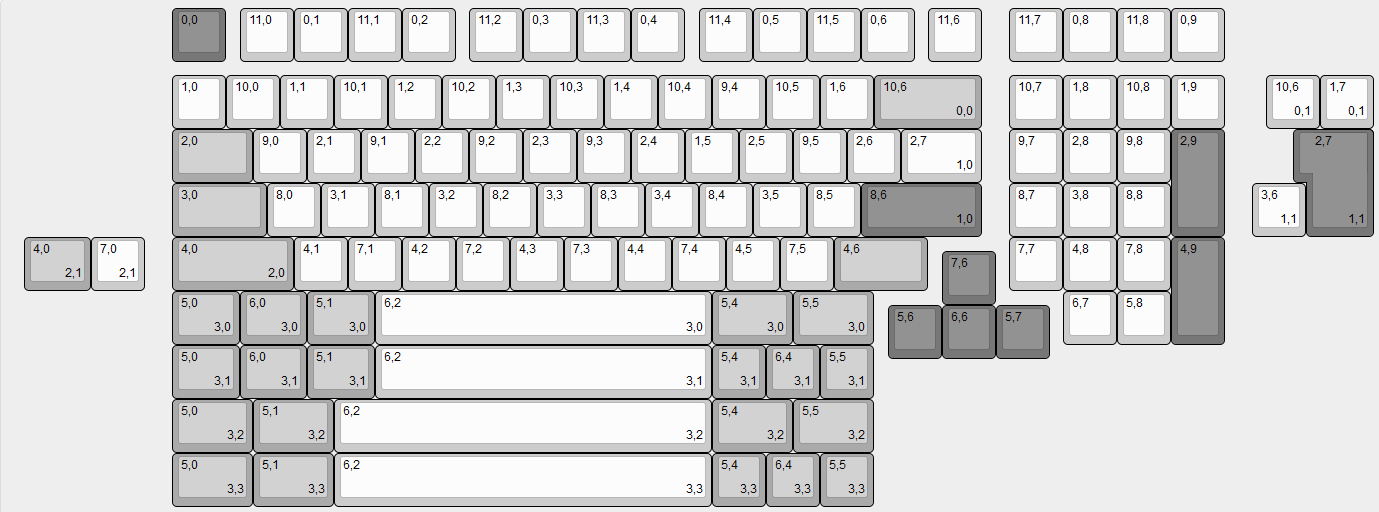

KLE is used to map keys to row/column and define layout options, to be exported later on in Json format for VIA software.

Here is the result on the Winghead:

I discovered that doing that work on KLE makes you easily see the switch matrix topology, I saw that some of my switch row/colum placement could have been better.

Next time I’ll do that step before starting designing a switch matrix on Kicad.

After a few trial and errors I had the following result on VIA ![]()

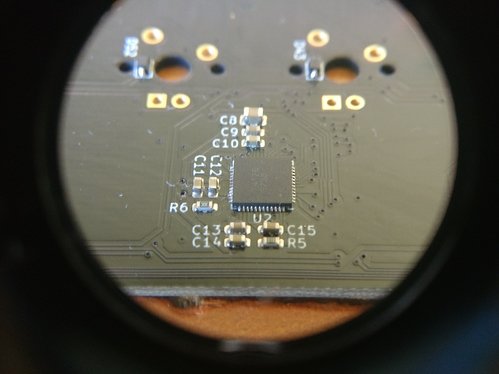

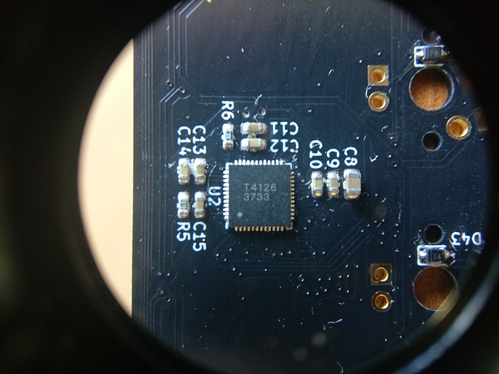

Next step, make a second PCB and find a way to solder the LED driver this time ![]()